Inductive forklift battery and batterytray: etaTRAY

Forklift, lifting device and industrial truck inductive charger

etaTRAY is a Plug-and-Play forklift battery as a retrofit for your industrial truck with wireless charging. Available for all standard industrial truck battery trays with battery capacities of 100–240 Ah. No matter if you charge your forklift with 12V, 24V or even 48V batteries. This is the One-4-All system.

Old industrial trucks and forklifts still have a lot of life left in them. Instead of throwing them on the scrap heap, you can replace their standard lead-acid battery (PzS) trays with our Li-Ion etaSTORE battery pack in just a few steps. This retrofitting solution combines inductive power transmission, intelligent wireless charging technology and lithium-ion batteries to make old vehicles fit for the future

Our inductive batterytray with battery packs for forklifts, electro forklifts, lifting devices and tugger trains. Simply stopping your vehicle at the charging position will start your charging process. Thanks to the contact free design, the charging system may be installed where ever your process requires, i.e. loading and unloading stations. There are no trip hazards and charging will start within less than a second. For optimized charging of lithium batteries a CAN-interface to communicate with your vehicle components is part of the system. At the end no forklift battery charging station is even more needed, because its possible to use in opportunity charging manually.

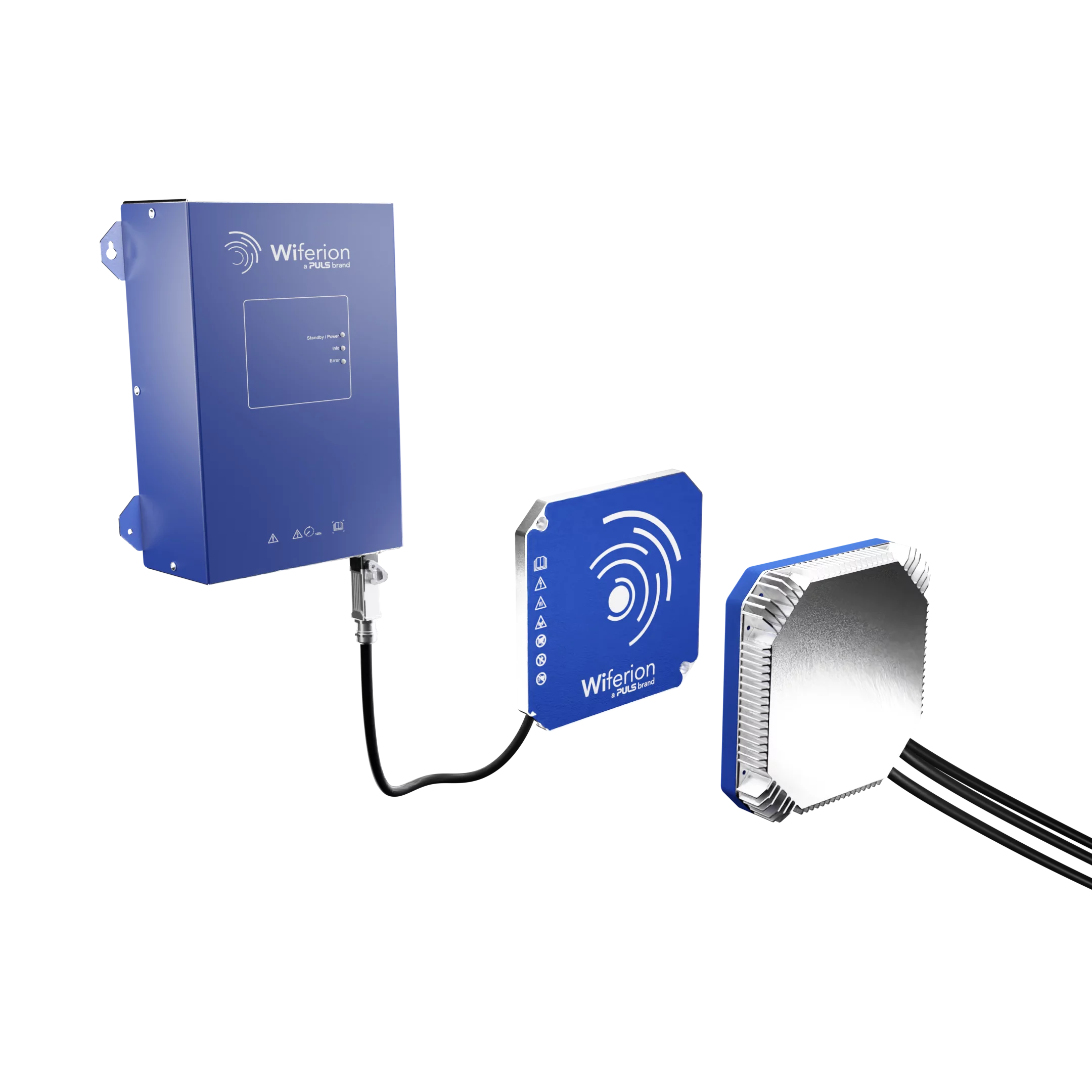

Contactless forklift battery charger without cable

The patented charging technology from Wiferion consists of a stationary transmitter unit with wallbox and charging pad as well as receiving electronics, which is installed in battery tray. If a vehicle drives on or next to the charging station, the charging process begins in less than a second. So, there is no need for an additional battery charger anymore. It does not matter from which direction the charging station is approached. With optimized lithium-ion battery packs is etaTRAY the last battery you have to switch and never need an additional battery charger again.

An integrated CAN interface transmits data on the battery status and energy level to the fleet management. etaTRAY, etaLINK 3000 and the etaLINK 12000 system, is compatible with all available battery systems so it doesn’t matter if STILL, Jungheinrich, Linde or any other industrial truck producer.

- Wireless charging saves time

- Higher safety without cables or the need of connectors

- Batterystations are almost completely eliminated

- Productivity increases due to higher vehicle availability

- No peak loads during charging thanks to In-Process-Charging

Individual battery tray and battery for your vehicle

We can offer you a forklift battery, industrial truck battery, tugger train battery and traction batteries with our tugger train and forklift charging station. The batteries are reliable and much more durable than the classic lead-acid batteries. For your safety at work, you have to rely on the fact that your truck works properly, so it is important to have a high-quality forklift battery with a charger. All of our batteries allow a very long runtime and high performance from beginning, as well as during the lifetime of your industrial truck.

The Evolution of Forklift Charging Systems

Traditionally, forklifts were powered by internal combustion engines, but today, electric forklifts have become increasingly popular. These require charging stations where they can power up during breaks or after working hours. But here comes the twist: imagine a world where forklifts charge themselves, wirelessly!

Introducing Wireless Charging for Forklifts

Yes, you heard it right! The concept of wireless charging isn’t new, but its application to heavy machinery like forklifts is a groundbreaking achievement.

The Mechanism of Wireless Charging

This is where it gets fascinating. Wireless charging operates on the principle of inductive charging.

Understanding Inductive Charging

Inductive charging is a process where electrical energy is transferred between two objects through an electromagnetic field. This happens via two components: a transmitter and a receiver.

Coil Design and Positioning

The transmitter, connected to a power source, generates an electromagnetic field. The receiver, fitted in the forklift, uses coils designed to capture this energy.

Power Transfer and Conversion

The receiver coil converts the captured energy into electricity to charge the forklift’s battery. It’s as simple and seamless as that!

Implementing Wireless Charging in Forklifts

It’s a revolutionary concept, to have forklifts recharge automatically whenever they’re not in use. This eliminates the need for plug-in charging and saves valuable time.

Advantages of Wireless Charging

One significant advantage is the reduction of wear and tear on physical connectors, which extends the lifespan of the charging system.

Evaluating the Benefits of Wireless Forklift Charging

Wireless charging brings along a host of benefits that can revolutionize the logistics and supply chain industry.

Increasing Operational Efficiency

Wireless charging eliminates downtime, as forklifts can be topped up whenever they are idle, even for brief periods.

Enhancing Safety Measures

With no cables to trip over or high voltage connections to manage, wireless charging also enhances safety within the working environment.

Contributing to Sustainability Goals

Wireless charging reduces energy waste, aligning with the industry’s push towards sustainability and green logistics.

Better

- etaLINK achieves efficiency of up to 93% during the transfer of energy.

- The charging process begins within 1 second.

- The system complies with the IP65 & IP68 protection class, making it suitable for use outdoors and in harsh environments.

Simpler

- AGVs and other logistics vehicles can simply be driven up to the charging pad from any direction and a high position tolerance is guaranteed.

- Thanks to their small dimensions, the mobile units can even be fitted into compact vehicles.

- Management, consumption and telemetry data is transferred to the charging pads contactlessly via infrared interfaces, allowing the system to be digitally integrated into the logistics process.

Cheaper

Specifications etaTRAY

| etaTRAY | |

|---|---|

| Continuous charging power | 3000 W – 6000 W |

| Charging voltage | 15 – 60 V |

| Charging current | 60 A – 120 A |

| Protection class | IP65 und IP68 |

| Optimum distance | 15 – 40 mm |

| Position tolerance | +/– 30 mm |

| Size / Dimensions | Individual for your vehicle |

Discover our different wireless charging and battery solutions

Buy the forklift battery, request a quote or ask more questions

Let us advise you about your battery tray, industrial truck battery and charger, also in a personal conversation. We will find the right and individual charging solution for you based on your vehicle details and fleet size.

Frequently Asked Questions

- How does wireless forklift charging work?

- It works through inductive charging where energy is transferred between a transmitter and a receiver via an electromagnetic field.

- Is wireless charging for forklifts safe?

- Yes, it is safe. In fact, it enhances safety by eliminating high voltage connections and trip hazards from cables.

- Does wireless charging extend the battery life of forklifts?

- Yes, it reduces wear and tear on physical connectors, which can extend the lifespan of the charging system and battery.

- What are the challenges of wireless forklift charging?

- Initial setup costs are a bit higher, and specific alignments are required for optimal charging.

- What is the future of wireless charging in forklifts?

- It is expected to become the standard in forklift technology, improving efficiency and safety.