INDUSTRIAL WIRELESS CHARGING & LITHIUM BATTERIES

Contactless wireless charging for industrial trucks, autonomous guided vehicles (AGV) and autonomous mobile robots (AMR / CoBot)

INDUSTRIAL WIRELESS CHARGING & LITHIUM BATTERIES

Contactless wireless charging for industrial trucks, autonomous guided vehicles (AGV) and autonomous mobile robots (AMR / CoBot)

INDUSTRIAL WIRELESS CHARGING & LITHIUM BATTERIES

Contactless wireless charging for industrial trucks, autonomous guided vehicles (AGV) and autonomous mobile robots (AMR / CoBot)

“The chargers can be installed without major changes to the building structure. This is a big advantage, because many companies only rent the warehouse. We were also convinced by the high reliability and durability.” – Peter de Kiewit, Sales Director at Lowpad

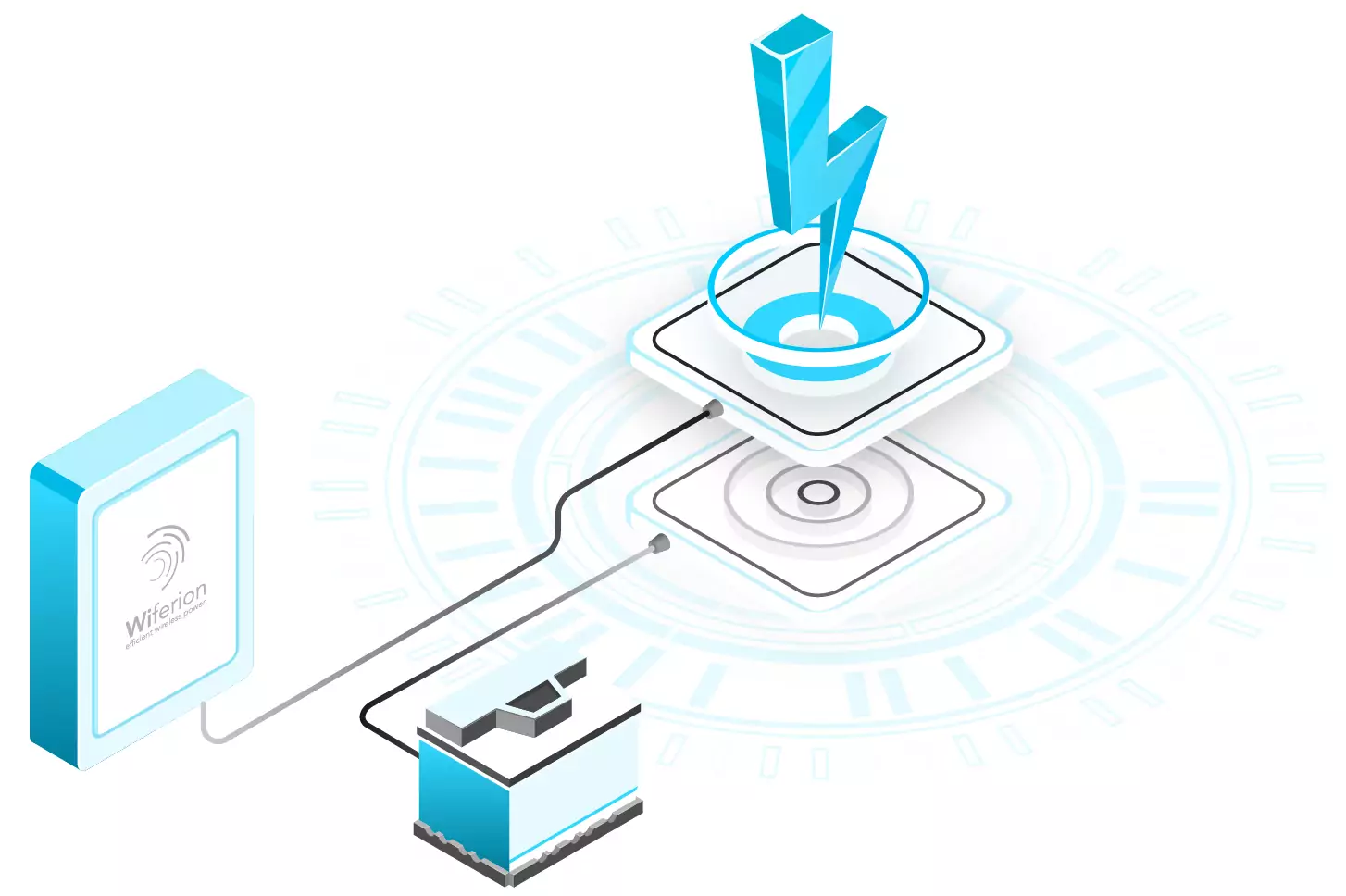

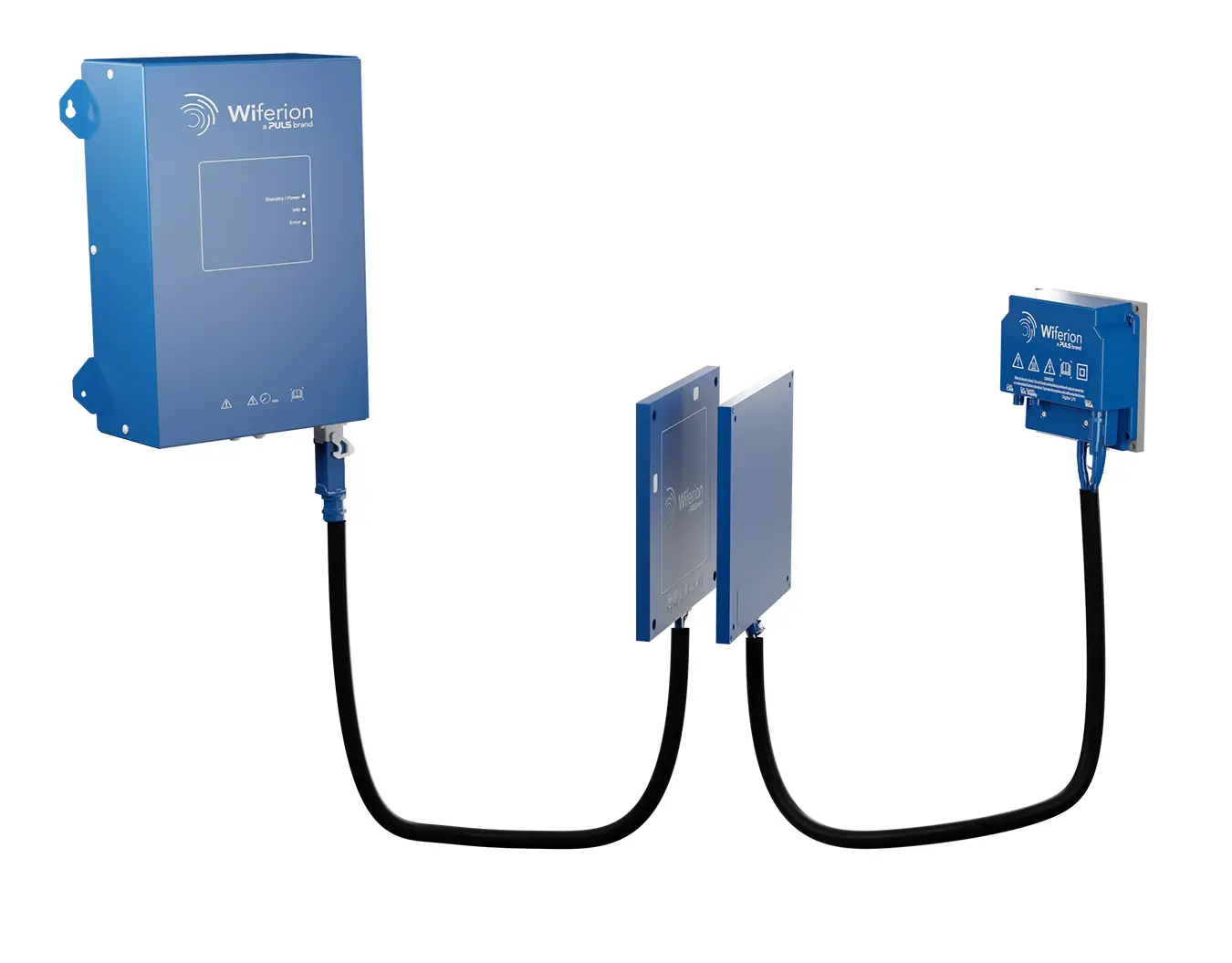

WIRELESS, INDUCTIVE CHARGING FOR AGV & AMR, FORKLIFT AND INDUSTRIAL TRUCKS

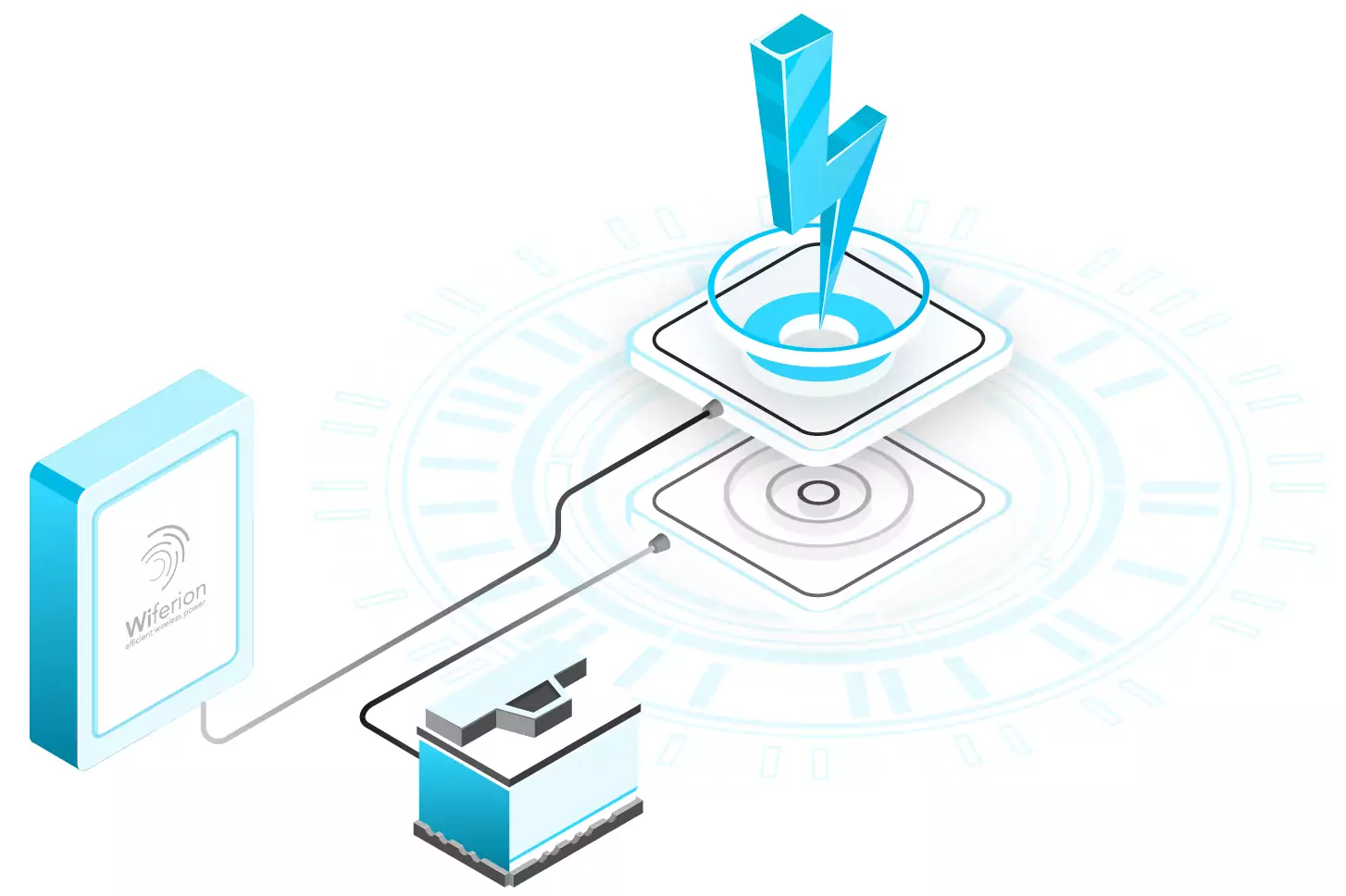

Increase your vehicle availability with Wiferion’s wireless inductive charger. Our system can charge your entire fleet with just one charging station, no matter what voltage, current and even battery type they have as well as collect data on capacity, energy status and much more!

Why Wiferion?

We do not see the wireless inductive power coils as independent components, but as an integral part of the power electronics. Thanks to our in-depth knowledge of simulation and dimensioning of coils and electronics, we are able to develop highly efficient, compact charging systems for any application.

Experience Wiferion live at our events and convince yourself of inductive charging!

The power of etaLINK. Why your customer will love etaLINK and Wiferion.

With our extensive experience in the field of power electronics, we have supported the development of numerous power converter systems for the e-mobility, energy storage and renewable energy sectors.

Wireless charging with 1000 Watt

The new CW1000 system from Wiferion with 1kW is based on our many years of experience and expertise in the field of efficient energy supply. This has enabled us to develop a contactless charging system that combines electronics and coils. As a result, the system offers numerous advantages such as a compact design, intelligent energy supply and a cost-efficient and reliable power supply for small robots. The system can simply be connected directly to the battery, making it a particularly simple and practical solution.

Wireless charging with 3000 Watt

etaLINK 3000 is a patented inductive charging system for industrial electric vehicles and mobile robots. Our charging systems are designed for the latest generation of smart and autonomous robotic systems. Easy and independent to install, they provide the vehicles with all relevant data. Since the systems do not require plug-in or sliding contacts, they enable intermediate charging of the batteries. This so-called “in-process charging” not only saves time, but is also safer than charging via potentially dangerous open contacts. etaLINK charging systems are maintenance-free and designed for many years of continuous use, e.g. in logistics or production. Furthermore, the inductive charger works with any type of battery.

etaSTORE LFP

| Lithium iron phosphate – The optimal solution for continuous use | |

|---|---|

| Capacity (nominal) | 21 Ah |

| System voltage | 24 V |

| Charging rate (C-rate) | up to 2 C |

| Cycles | < 7500 |

| Charging current | 42 A |

| Number of batteries per system |

max. 20 |

| Communication system | CAN-BUS |

| IP protection | IP54 |

| Dimensions (W x H x D) | 13.2 cm x 18 cm x 19.5 cm |

Modular, connectable in series and with an integrated BMS. With a high charging rate of up to 2C, etaSTORE LFP can be charged from 0-100% in the fastest case in around 30 minutes .

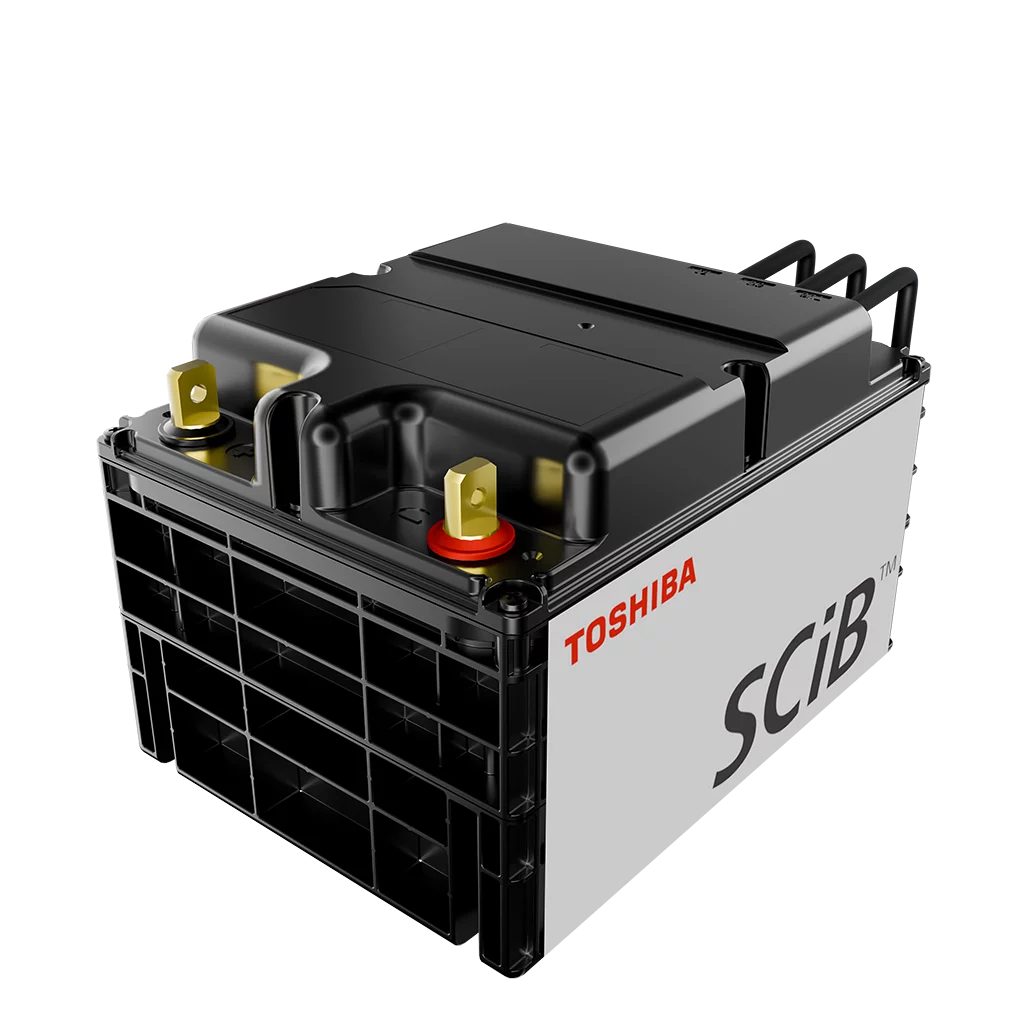

etaSTORE LTO

| Lithium titanate – the right choice for high charging currents and many charging cycles per day | |

|---|---|

| Capacity (nominal) | 22 Ah |

| System voltage | 24 V or 48 V |

| Charge rate (C-rate) | up to 5 C |

| Cycles | < 17000 |

| Charging current | < 125 A |

| Number of batteries per system |

max. 2 |

| Communication system | CAN-BUS |

| IP protection | IP53 |

| Dimensions (W x H x D) | 247 x 165 x 188 mm |

Modular, connectable in series and connectable in series with integrated BMS. With a charging rate of up to 5 C, etaSTORE LTO (lithium titanate) can be charged from 0-100% in around 12 minutes.

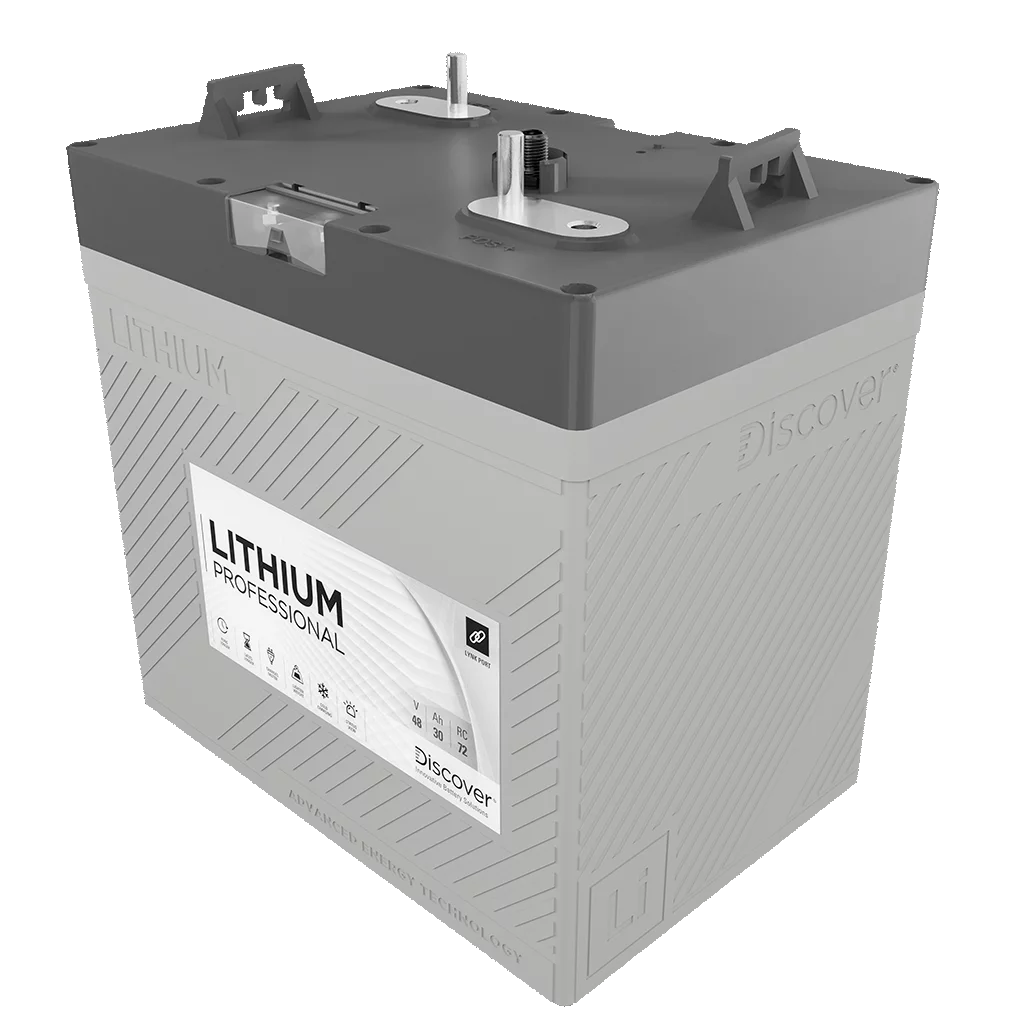

Lithium iron phosphate – optimal price–performance ratio for demanding applications

| Lithium iron phosphate – optimal price-performance ratio for demanding applications | |

|---|---|

| Capacity (nominal) | 60 Ah (24 V) or 30 Ah (48 V) |

| System voltage | 24 V or 48 V |

| Charge rate (C-rate) | up to 1 C |

| Cycles | < 3000 |

| Number of batteries per system |

max. 2 |

| Communication system | CAN-BUS |

| IP protection | IP67 |

| Dimensions (W x H x D) | 260 x 275 x 180 mm |

Modular, connectable in series, and with integrated BMS. With a charging rate of up to 1 C, the Discover cells can be charged from 0-100% in around 60 minutes in the fastest case.

“Our omni-directional AGVs can approach the charging station from multiple directions and automatically start the charging process. This is a huge increase in flexibility when creating system designs for different projects.” – W. Bohlken, Head of R&D Mobile Robotics, KUKA Germany

Why your customer and your robot will love etaLINK

Open up the limitless possibilities of robotics for your company.

- Lean & Clean

- Eliminates services

- Safe and reliable

- Easy to integrate plug-and-play system (CE and comply with UL1564 and CSA C22.2 No. 107.2)

- Can be approached from any direction

- Large position tolerance, maximum freedom in AMR route design

- Perfect Robot-as-a-Service business

- High competitiveness in project tenders

- Transparent pricing, no hidden costs

WIRELESS INDUCTIVE CHARGING AT A GLANCE

Compact Electronics

With our extensive experience in power electronics we have supported the development of numerous power converter systems for e-mobility, energy storage and renewable energies.

Innovative Coils

We do not see the wireless, inductive power coils as independent components, but as an integral part of the power electronics. Thanks to our in-depth knowledge of simulation and dimensioning of coils and electronics, we are able to develop highly efficient, compact charging systems for any application.

Scalable infrastructure

With efficient infrastructure solutions, we and our partner offer installation options for flush-floor,

raised floor or on-floor mounting that meet your needs.

ADVANTAGES OF INDUCTIVE CHARGING

With an efficiency of 93%, our innovative etaLINK technology opens new horizons in the field of wireless inductive charging. Based on the principle of magnetic induction, we have developed innovations for several core areas of the system. Modern algorithms and the integrated communication interface to the battery management system (BMS) guarantee both smooth and fast battery charging processes.

WIRELESS CHARGING MAKES CONTINUOUS OPERATION OF DRIVERLESS TRANSPORT SYSTEMS POSSIBLE

With our inductive battery charging systems, we enable the continuous operation of AGVs and AMRs. Our innovative “in-process charging” allows the vehicles to be supplied with energy efficiently and fully automatically – without contact and without the vehicles having to interrupt their transport for charging breaks.

Applications or areas of use

Production logistics: More productivity through inductive charging

Logistics in warehouse and logistics area with wireless charging

Process optimization in E-Commerce and Fulfillment

Area of application and use according to vehicle type

Wireless Charging of AGVs

Wireless power for AMR

Automated tugger train: More productivity through inductive charging

What customers say about inductive charging

K. Franke

Head of Hardware Development

Magazino

“We were looking for a system provider that offered batteries, BMS and the chargers, and that they could be integrated in an easy and user-friendly way for our robots. We use the Wiferion system because it was incredibly compact for the power delivered and the batteries have the new ICE 62619 compliance for the industrial environment.”

D. Winling

Technical Manager

Norcan & Sherpa Mobile Robotics

“We actually found that the technology allows up to 10,000 charging cycles. Before, we were only at 1,000 cycles with our extra batteries.

That gives us a lot of flexibility, and you always have enough energy on board to run a fully autonomous system.”

W. Bohlken

Director of R&D Mobile Robotics

KUKA Augsburg

“In the medium term, the etaLINK system is wear-free and can help reduce energy costs thanks to its very good efficiency. In addition, our omnidirectional AGVs can approach the charging station from multiple directions and start the charging process independently. This also increases flexibility when creating system designs for different projects.”

Discover more application areas of inductive charging

WIRELESS CHARGING TECHNOLOGY FOR AGV, INDUSTRIAL TRUCKS & MOBILE ROBOTS

etaLINK 3000 and CW1000 are patented wireless charging systems for industrial electric vehicles and mobile robots. Our chargers are designed for the latest generation of smart and autonomous robots. Easy and independent to install, they provide the vehicles with all relevant data. Since the systems do not require plug and sliding contacts, they enable fast intermediate charging of the batteries. This so-called “in-process charging” not only saves time, but is also safer than charging via potentially dangerous open contacts. etaLINK charging systems are maintenance-free and designed for many years of continuous use.