Lower energy costs, longer battery operating life and safer processes – with the etaHUB charge optimization platform (COP), Wiferion is presenting the world’s first solution for smart robot charging at LogiMAT 2023. In Hall 6, booth 6C45, industrial companies can see for themselves how smart robot charging uses intelligent charging management to lower the power consumption of autonomous guided vehicles (AGV) and autonomous mobile robots (AMR), extend battery operating life and improve productivity.

Visit us at LogiMAT 2023 from 24th to 27th April – Hall 6 – 6C45

LogiMAT 2023: Wiferion presents world’s first charge optimization platform

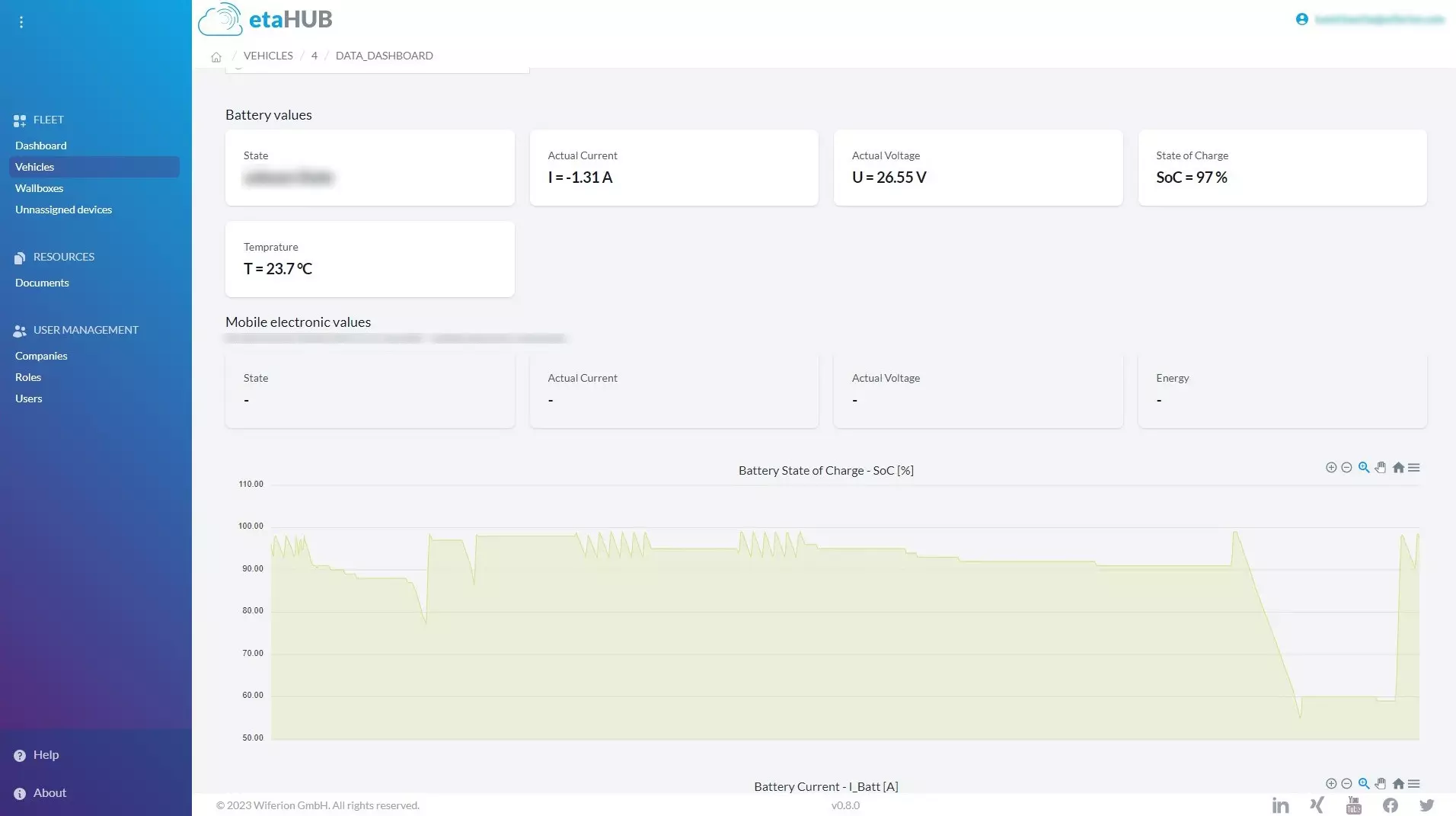

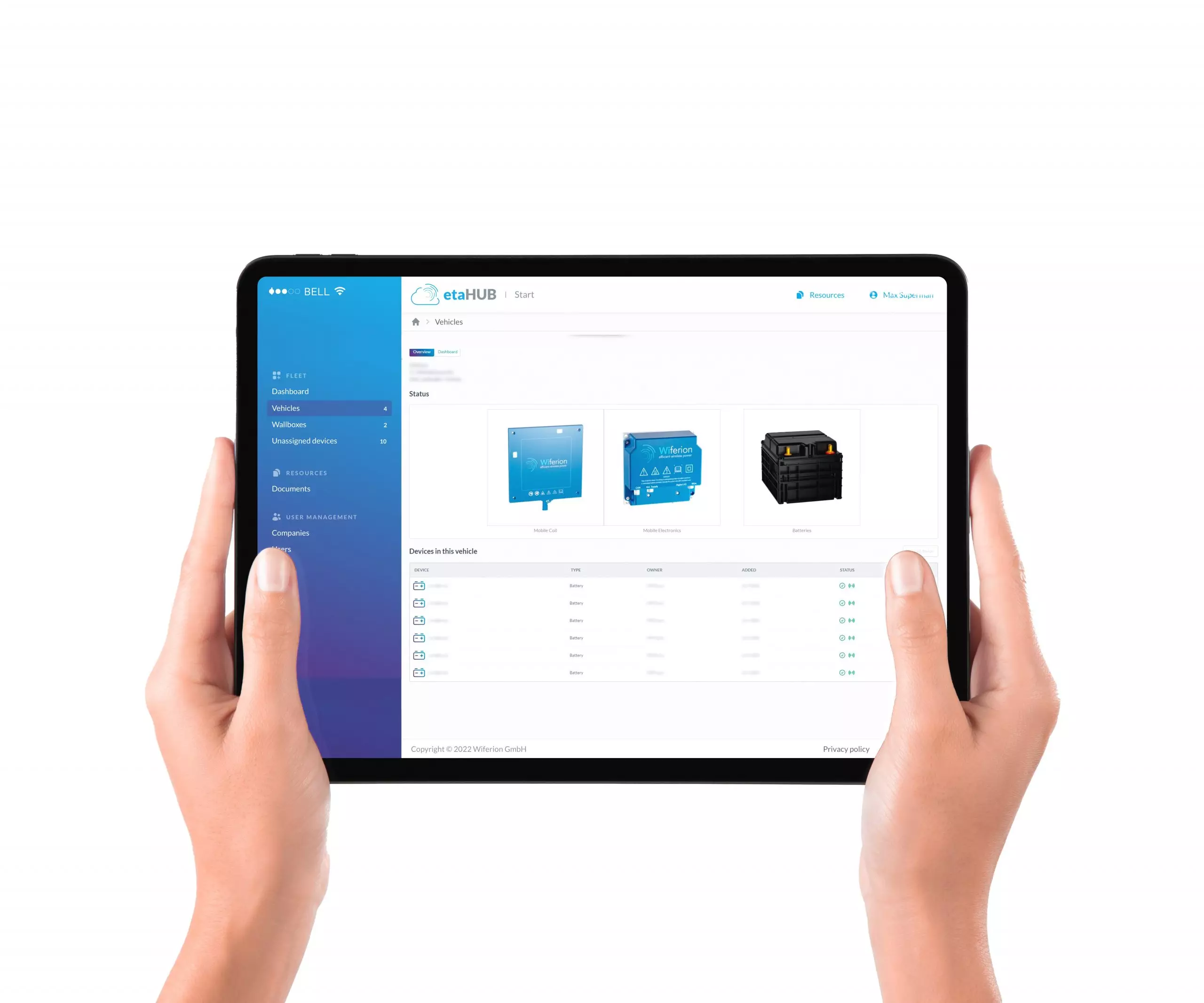

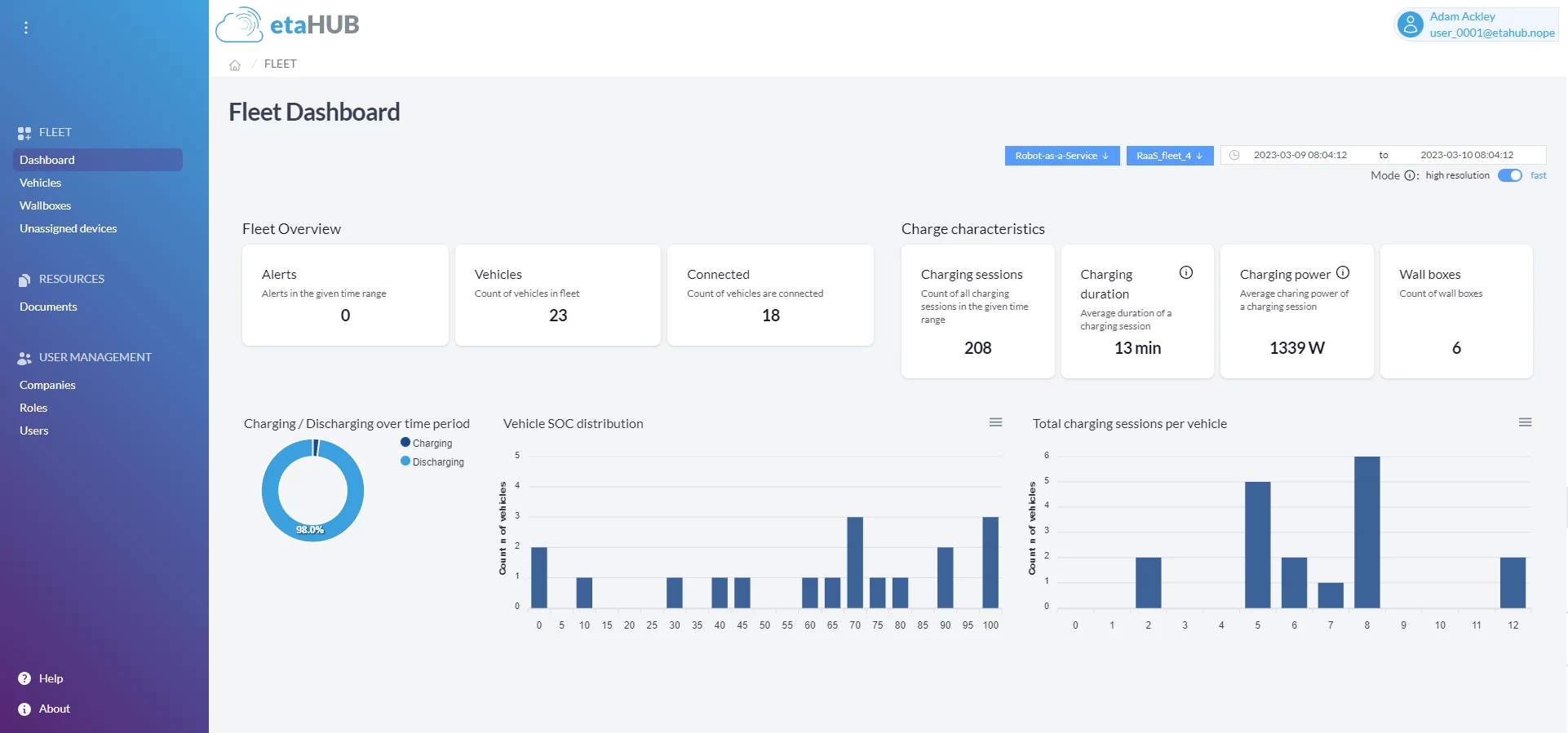

With the cloud-based etaHUB IoT application, companies can utilize their robot fleets even more efficiently. The intelligent algorithms of the charge optimization platform analyze the energy data that Wiferion, as the sole supplier in the market, determines with its inductive charging systems and batteries. The evaluation of more than 70 data points such as battery temperature, mains voltage and battery state (state of health, SoH) opens up the possibility of smart robot charging for mobile robots for the first time.

Smart robot charging optimizes the power supply to AGV and AMR in three central areas.

- Data monitoring and alarms

etaHUB monitors the charging status of AGVand AMR in real time. If an error occurs in the energy system, this is shown in the dashboard and can be analyzed. Notification by email or SMS is also possible. There is no longer any need for a service technician on the spot. This is an advantage as robot fleets increase in size and are distributed across a number of locations. On the basis of the comprehensive energy data, the intelligent software draws up forecasts of the likely battery operating life. This means that the maintenance or replacement of the battery can be planned at an early stage before robot malfunctions can occur. The tool collects all the information centrally in a battery pass. Maintenance and servicing costs for AGV projects decrease dramatically. - Adjusting the charging power

With smart robot charging, the battery operating life can be extended by up to 10% by intelligently controlling the charging cycles and the charging and discharging rate (C rate). etaHUB reduces the C rate in periods with fewer transport orders in order to protect the battery, and increases the charging rate when the robots have to process more orders.

- Adjusting robot behavior

By integrating the etaHUB into a fleet manager, the availability of the vehicles can be increased. etaHUB provides precise data about the duration of a charging process and about when which robots will be at a charging point in the future. The fleet manager can plan the AGV precisely so that there are no redundant charging times. The availability of the robot increases. In addition, the charge optimization platform improves safety in production. If the battery temperature is too high, the system communicates with the fleet manager so that the robot can be moved to a safe place.

Charging when it’s cheaper – LogiMAT 2023

etaHUB helps companies to save on energy costs. Smart charging makes it possible to plan the charging times of mobile robots so that they correspond to the times when power costs are at their lowest. It could be cheaper, for example, to charge batteries at night when the need for power is lower. It is also possible to couple this with data about the energy mix (proportion of renewable energies) from energy management systems or data from the Fraunhofer Institute. All of this will be on display for the first time at LogiMAT 2023.

Network utilization is improved

In addition, the Wiferion solution improves network utilization, as not all the robots are charged at the same time, e.g. at the end of the shift. Florian Reiners, CEO and co-founder of Wiferion, is certain: “The market for transport robots and batteries is growing exponentially. Smart charging is the essential requirement for being able to scale automated robot and automation solutions robustly.”