Charging contacts and inductive charging for vehicles

Charging contacts compared to the advantages of Wiferion battery charging station for vehicles

What are Charging Contacts?

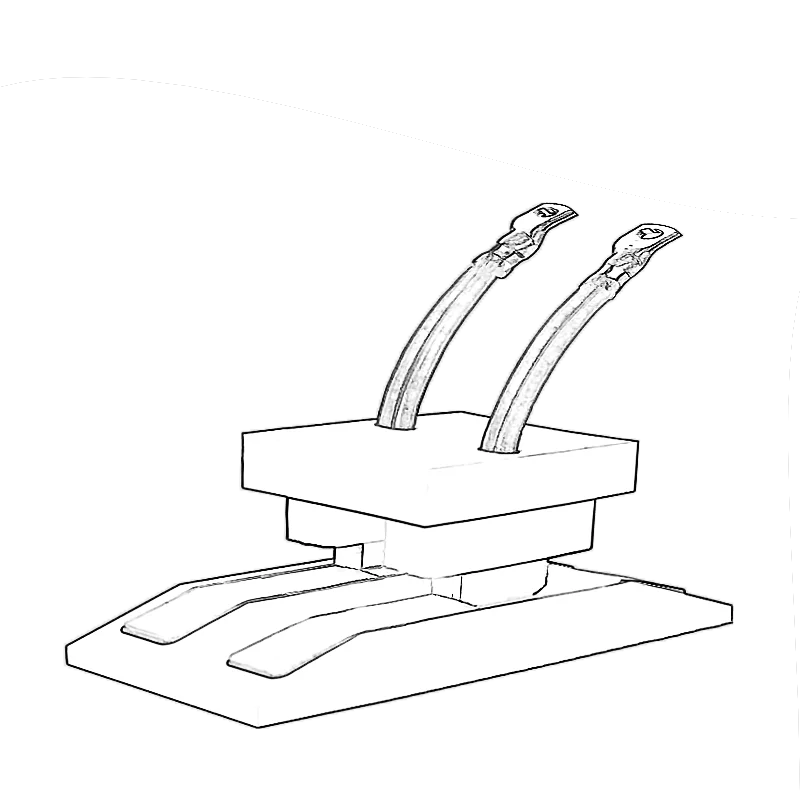

Today’s batteries that are charged in autonomous guided vehicles and mobile robots are mostly based on the century-old system of charging contacts at the end of springs, first patented in 1899.

Spring-loaded collector contacts (spring contacts) drag or hang below the mobile robot in use and have low ground clearance and narrow height tolerance because they must physically slide up a ramp on the base: If they are mounted too low, they touch the floor or hit the side of the pedestal. If they are mounted too high, charging contacts have weak spring pressure or have no contact at all. Over time, they also have a high wear rate because the charging contacts are constantly sliding across the charging surfaces.

The magnetic effect of the charging contacts are complex, heavy, bulky and expensive systems whose capacity is nowhere near the capacity of large copper contacts that physically press against each other. The applications thus very specific and limited.

High current charging station with low profile

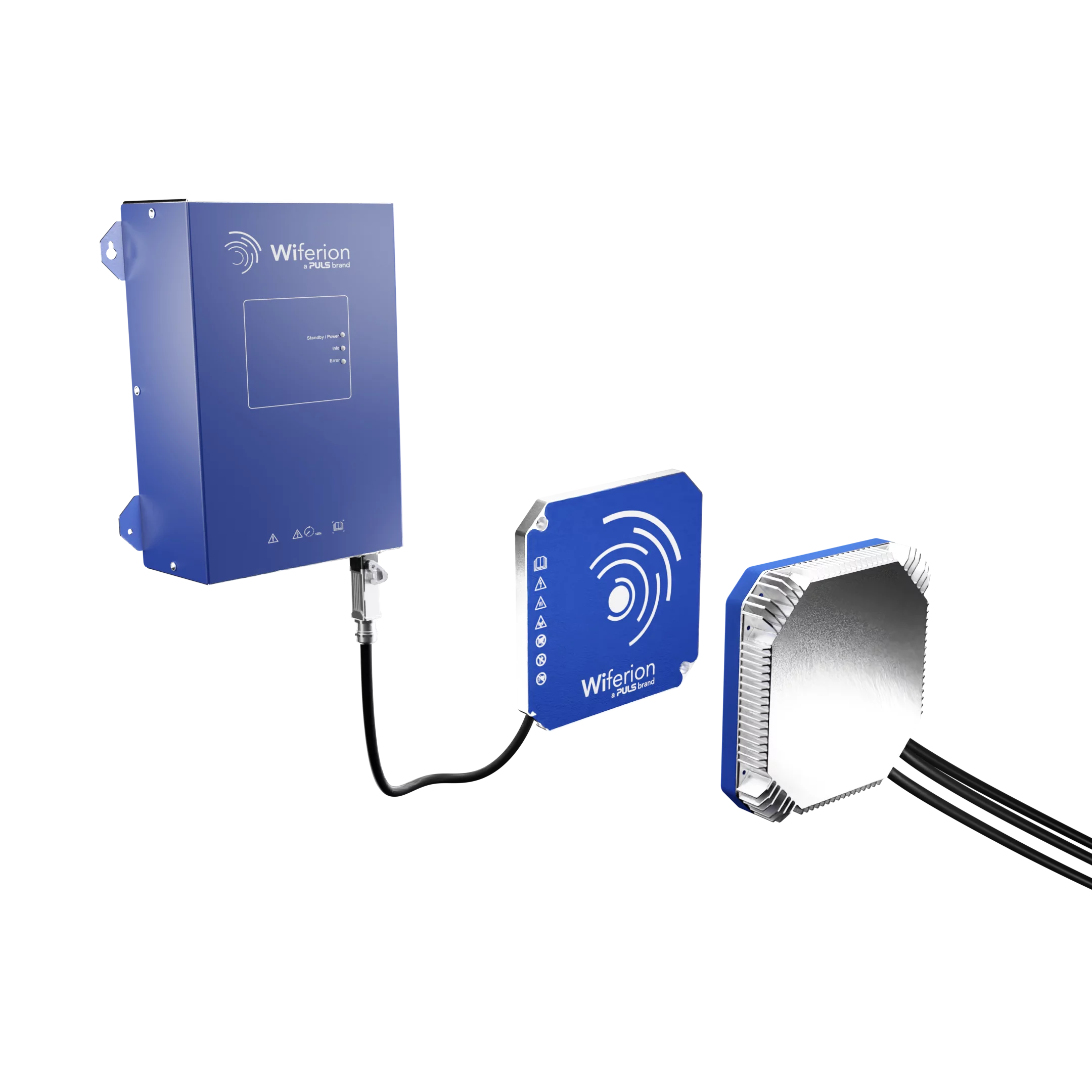

Our inductive charging system provides a precise high current charging solution for mobile robots and Automated Guided Vehicles (AGV). Unlike a charging contact, it consists of a stationary pad, typically mounted on the ground, and a mobile unit mounted on the vehicle. Wiferion uses magnetic resonance based inductive energy transfer without the need for additional energy from the battery. The very low profile of the stationary charging unit and the mobile pad allow for much more compact charging configurations than any other battery charging system and thus more application areas. Its also fitted for the perfect opportunity charging of batteries.

Completely wireless charging – works like magnetic magic

The inductive charging system works according to Tesla’s resonant-inductive coupling principles.

The resonance between the oscillating circuits leads to an improved magnetic coupling

between the transmitting and receiving coils at the transmission frequency.

Approach

Unlike collector pads that are attracted by magnets or spring contacts, inductive charging is completely operational without touch/contact. This also prevents wear and tear such as with the charging contact system, as these are simply not present and no contact takes place. The vehicle drives safely with a very high ground clearance.

Also, with the pads of Wiferion other data, such as the health of the batteries or other freely configurable components are transmitted directly with. This is not found with a charging contact.

Charging

When arriving from all directions, the charging process starts automatically as soon as the robot or the vehicle is within range. This happens not only when the vehicle is over the center of the charging base, but already during the approach from different directions. With charging contacts such as spring contacts, the direction must be correct and approached very precisely.

Disconnect the charging

When the robot moves again, the charging process also ends automatically. There is no need to push back a charging contact or spring contact, which could even get stuck.

The robot can then continue its course with the safe pads and a high ground clearance and that with always high battery charge level.

Fit – Lightweight

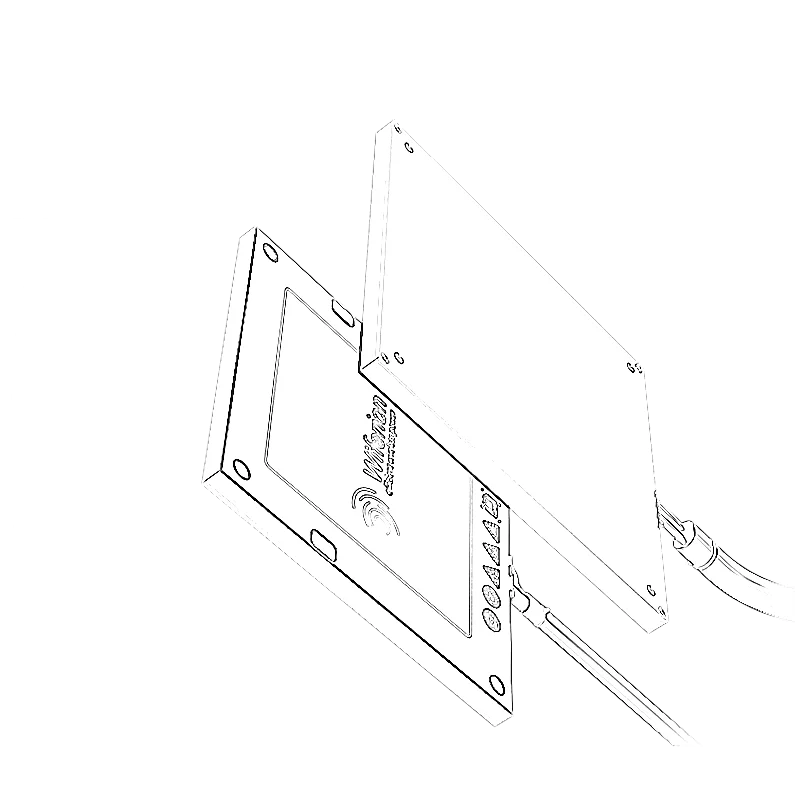

Thanks to the ground clearance and compact design, our inductive chargers achieve extremely high efficiency and safety for different vehicles at the same time, as the voltages are always specified by Mobile induction device. Thus, one charger can seamlessly meet a wide variety of requirements for charging current, charging voltage and even battery technologies. Thus, they do not have bulky and heavy spring contacts or charging contact designed for only one voltage and current. As a result, they carry the highest current for their relative size. They can be mounted horizontally as well as vertically in your vehicle. The charging pad can be used flush as well as behind the panel.

Scalable from small to huge

The applicability of inductive charging systems is fully scalable and configurable. There is a small version with 3kW charging current that also works on the standard Schuko socket, as well as a 12kW charging current version. Both systems have all the advantages of inductive charging and differ only in the dimensions of the wireless charging pads.

Designed to keep your vehicle moving

Mobile robots only pay for themselves when they are moving. Our charging system helps maximize their value by providing fast, high-current charges that minimize their idle time. The Charging Pads’ low-cost, ultra-low profile makes it easy and cost-effective to place charging stations along the robot’s path at any point where the robot normally pauses for more than a few seconds. Contactless charging eliminates the need for battery changes or plug in charging.

Easy integration into your flow management

In most cases, the ground-mounted inductive charging stations are placed at specific waypoints in the robot’s path. The robot/vehicle then stops at that specific location and automatically charges using the charger (opportunity charging of batteries).

To charge, the robot or AGV simply moves over the charging pads on the ground. When the robot’s charging pads reach the stationary pads, the charging process starts in under one second. By directly sensing the charging voltage or by monitoring the sensor built into the Charging Pads, the robot can determine when it needs to stop. Current can then flow to the battery to charge it and data can be transferred.

What makes wireless charging better than contact charging?

| System | Charge current | Charging detection | Ground clearance | Reliability | Size | Initial cost | Follow-up costs |

|---|---|---|---|---|---|---|---|

| Charge contacts | Highest | Yes | Low | Low | Medium | Low | Medium |

| Spring contacts | Low | No | Low | Low | Large | Low | High |

| Wiferion wireless charging | High | Yes | High | Highest | Compact | Medium | None |

Charger only active during direct use

The inductive charging system is also only ever active as soon as a mobile charging coil approaches a stationary one directly. Thus, short circuits, flying sparks or similar are completely excluded even by the encapsulated systems.

With charging contacts, there are worst case switches built into the contacts and into the charging station. In this case, the charging contacts solutions have to be switched on and off manually.

Cost reduction compared to automated charging with charging contacts

You no longer need redundant charging stations for tugger trains or forklifts and therefore no longer have to worry about destroyed and unusable charging contacts. Due to the reliability of inductive charging, the vehicles do not have to be hybrid combustion engines and you can also trust in the complete electrification of your fleet. In addition, you also have significantly lower costs due to the variant reduction of the chargers, since inductive, contactless chargers can handle an all-in-one concept with a wide variety of voltage and current levels in just one charging station.

Applications of the inductive alternative to contact charging springs

Optimal for charging

- Driverless autonomous guided vehicles (AGV)

- Shuttle Systems

- All battery-powered vehicles in manufacturing and production facilities, assembly lines, high-bay warehouses, goods distribution centers and amusement parks.

- Driverless transportation systems

- Forklift charging

- Tugger Train charging

- Industrial truck charging

- Rides and amusement rides

- Autonomous robotics

Features of contactless charging

- Variable current ratings up to 400 A

- Variable transmission voltage from 24-120 V

- Integrated data transmission

- Integrated CAN interface

- Versions as vertical or horizontal solution

- No spare parts necessary since friction- and therefore wear-free

- Service Free

Customizing the charging process

- Constructive support in every project phase

- Calculation of ROI in your individual case

- Customized solutions and integrations