Lithium battery tray with inductive charging to retrofit forklifts

With the complete system of battery and wireless chargers

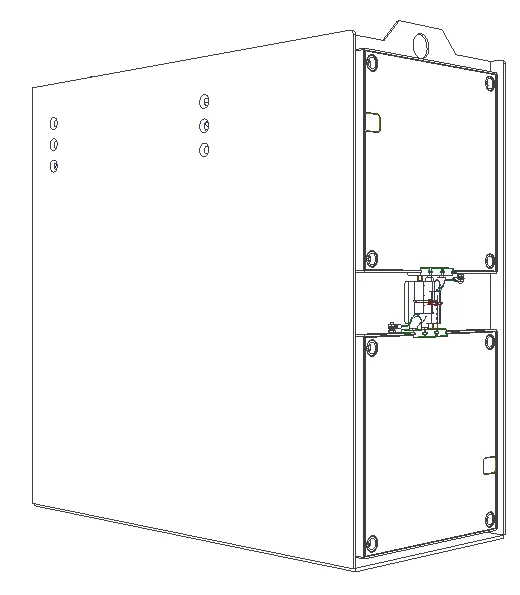

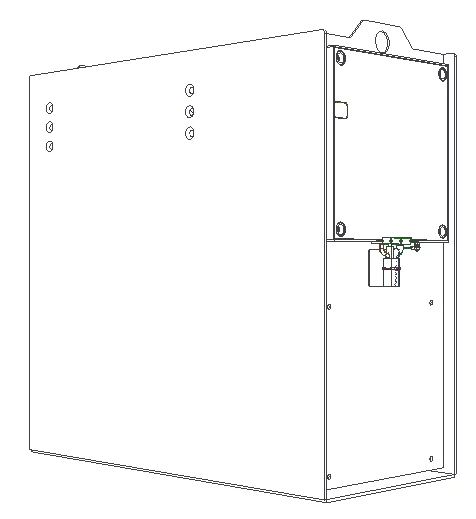

With the etaTRAY 3000s, Wiferion has developed a complete system. The complete system consists of the charger, lithium batteries and the vehicle specific battery tray. Thanks to the etaTRAY, in combation with the etaLINK 3000 wireless charging system, operators of industrial trucks can stop during the work process and charge. This gives the user the opportunity to charge the battery without connecting charging cables.

This in-process charging takes less than a second to start and can be placed throughout the facility to optimize workflow. With this solution, we do away with the charging process as a separate work step. Additionally, depending on the design, we can do without additional charging breaks outside of the process. The availability of the vehicle is increased and the potential of lithium batteries can be fully exploited. As a further effect, the battery capacity can be reduced, since it is no longer a matter of holding out as long as possible until you have to reconnect the charging cable. This can reduce costs caused by time loss, multiple fleets and additional space requirements.

Forklift battery tray with cables or contacts

In the past, we have mainly focused on the autonomous vehicle market. We are also discovering more and more how useful the etaLINK system is in manual vehicle markets.

In addition to the fully integrated tray, there are also customers who have attached our charger externally in a horizontal direction. This provides an additional option for charging the battery. The positioning is then realized via a marking on the vehicle and floor or wall. This means that the driver knows exactly where to stop.

Two solutions for a status display were developed. This allows the driver to be sure that everything works correctly when loading without having to leave the vehicle.

The first approach is connecting the CAN display to either the stationary electronics or the mobile electronics. It can display the charging voltage and the charging current. In addition, the battery symbol turns green when charging. Further functions are to follow in the future.

etaLINK + etaSTORE = etaTRAY

The second approach is a signal tower that clearly indicates to the user that the system is charging or if there is an error. Both approaches make it easier for the user to use the Wiferion charging system. With little effort a person can immediately see that the charging process is working properly and the battery is being charged.

Specifications of the battery tray with wireless charging:

Weight: 373kg

Charging Current: variable up to 120A

(sizes are individually build for your vehicle)

Better

- The charging process begins within 1 second.

- The system complies with the IP65 & IP68 protection class, making it suitable for use outdoors and in harsh environments.

Simpler

- AGVs and other logistics vehicles can simply be driven up to the charging pad from any direction and a high position tolerance is guaranteed.

- Thanks to their small dimensions, the mobile units can even be fitted into compact vehicles.

Management, consumption and telemetry data is transferred to the charging pads contactlessly via infrared interfaces, allowing the system to be digitally integrated into the logistics process.

Cheaper

- In-Process-Charging may reduce the amount of peak current provided by your energy supplier.

- One charging pad can be used by a vast number of different vehicles.

- Changes to building infrastructure and special charging areas are not necessary.

- Wear parts, damage caused by improper use and problems caused by contamination all become things of the past.

Get more informations about the etaTRAY inductive batterytray for your forklift

Let us advise you about your battery tray, forklift battery and charging system, also in a personal conversation. We will find the suitable and individual charging solution for you based on your vehicle specifications and fleet size.