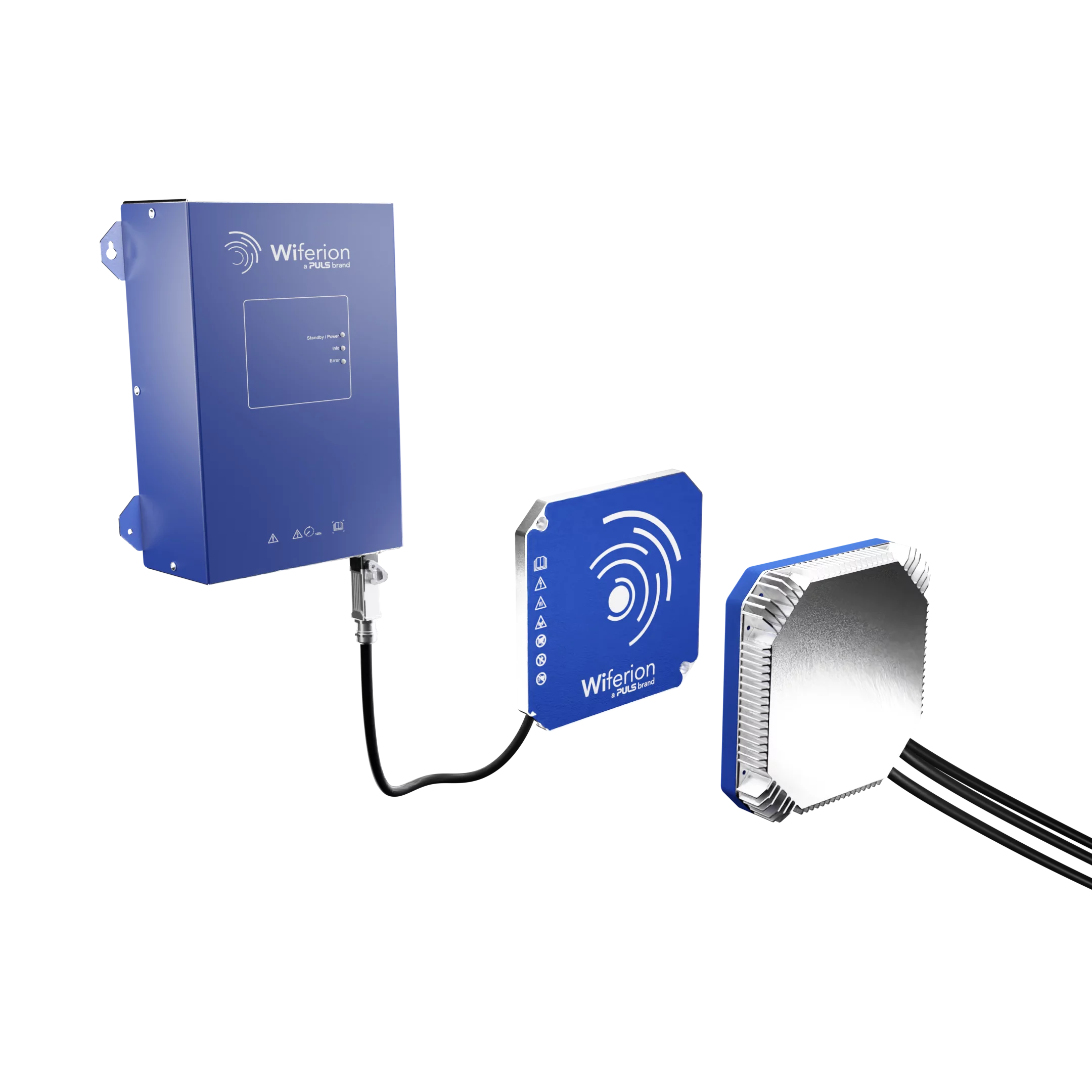

In the booming mobile robots market, goods-to-person robots are one of the fastest growing segments. With its new wireless charging system etaLINK 1000, Wiferion is making its successful wireless charging solution for small AMRs available for the first time. The new member of the etaLINK series is the ideal size for the compact design of fulfillment bots and transfers energy without contact with 1kW power.

Wireless charging solution for sorter, shuttle or commissioning applications

For sorter, shuttle or commissioning applications – the demand for small ARMs is massive worldwide. However, the supply of power to autonomous mobile robots (AMR) and automated guided vehicles (AGV) is not suitable for rapid expansion of fleets. Current energy solutions are frequently complex, energy-inefficient or unreliable. What leads to unproductive charging times, downtimes and expensive maintenance work. Wireless charging is therefore considered to be the new charging standard for mobile robots.

Due to the compact design, there are no reliable wireless charging solution for small AMRs available in the market to date. Wiferion is now filling this gap with its CW1000 system.

“In the last 3 years, we have sold more than 8000 3 kW and 12 kW systems. Our customers are so convinced of our technology that we are recording a massive demand for a smaller version of etaLINK. The etaLINK 1000 takes account of this development, enabling us to help our customers to charge their robots reliably and efficiently and to achieve productivity increases of up to 32%,” explains Julian Seume, Wiferion’s CSO.

“We are offering our customers a complete package comprising the charging system, perfectly matched batteries and comprehensive advice”

The new mobile charging unit that is integrated into the robot measures just 160 mm. That makes it 36% smaller than the etaLINK 3000. Another innovation is that the mobile electronics do not need to be fitted externally. Because they already are integrated into the charging pad. A sophisticated cooling system prevents excessive heat build-up. Equally, CW1000 has all the advantages of the larger models. Such as high positioning tolerance, maintenance-free operation and fast start-up of power transfer in around 1 second. Robot manufacturers will not only benefit from the wireless charging solution’s performance data:

“We are offering our customers a complete package comprising the charging system, perfectly matched batteries and comprehensive advice,” says Julian Seume.

In this way, Wiferion is supporting OEMs with configuring and implementing the energy systems in their robots and designing the appropriate charging layout for the end user. The recently presented etaHUB charge optimization platform is also used here.

According to Wiferion, numerous orders have already been placed. The technology company is expecting to sell up to 3,000 devices in the first year alone.