Whether aircraft parts, car bodies or ship propellers – in industry, heavy loads are often transported automatically to the processing stations by automated guided vehicles (AGVs) or floor conveyor vehicles (AGVs). Intelligent inductive charging technology is needed to operate the systems efficiently. With its Wireless Charging Protection System (WCPS), the PUK Group is launching a charging protection infrastructure that allows contactless power transmission to be implemented safely even in demanding environments.

PUK Group launches new Wireless Charging Protection System

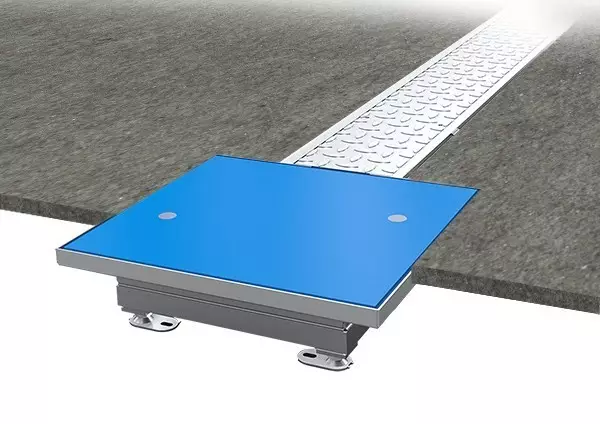

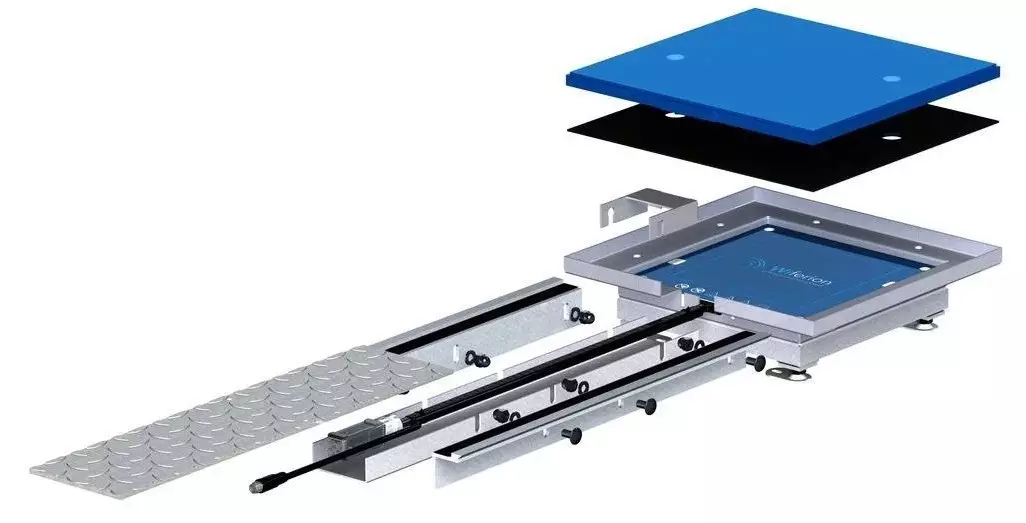

For the special requirements of modern electric vehicles in the industrial environment, the PUK Group has developed the new WCPS charging protection infrastructure for the etaLINK inductive battery charging system together with Wiferion. The cable routing expert thus protects the charging electronics from environmental influences in a coordinated system. The robust design and flush-floor integration make the solution particularly suitable for environments with intensive load cycling.

“In the manufacturing industries, the level of automation and the associated desire for performance-enhancing energy concepts are particularly high. However, transport vehicles weighing tons have been a limiting factor in the integration of our wireless charging technology. By working together with the specialists at PUK, we can now also serve this segment,” says Johannes Mayer, Managing Director of Wiferion.

Two components for maximum protection of AGVs

WCPS is a charging protection enclosure system that serves as a functional extension of PUK’s cable routing systems, thus combining tested functionality and optimum usability. The system consists of two components: the infinitely adjustable charging protection housing, which accommodates the charging pad, and the heavy-duty channel, which reliably protects the cable. Both units are connected via a quick connector. Both visible and invisible cable routing variants are possible. Further flexibility is provided by the possibility of retrofitting existing environments with the system with minimal intervention in the existing structure.

The protective cover is made of a heavy-duty and very thin PCX material, ensuring extremely high resistance to pressure, impact and shock. The maximum load capacity of the system is 15 kN. The WCPS is designed for retrofitting halls, but can also be easily integrated into new construction projects with an additional formwork body makes charging of AGVs safe.

About Pohlcon

Pohlcon Vertriebs GmbH, headquartered in Berlin, is the central contact for the three established brands PUK, Jordahl and H-Bau Technik. With the increasing complexity in planning, comprehensive consulting is becoming more and more important. By selling the three manufacturer brands together, Pohlcon facilitates orientation and creates a more user-friendly solution with a central contact for various trades and construction phases. The company employs staff with a wide range of different expertise and supports its customers from the outset with sales staff through consulting engineers to installation specialists for electrical installation.