Cutting Power Supply Costs in Existing Processes in Shuttle Sytems with Wireless Charging

The shortage of raw materials is becoming an increasing problem across the globe: Constantly increasing demand is accompanied by rapid price rises and reduced availability. This is also having a serious impact on copper. The material is used to supply power to shuttle systems in logistics warehouses. Because copper conductor lines kilometers long are installed, purchase costs are rising rapidly. There is therefore an increasing focus on concepts based on selective charging in elevators and in charging stations using power stores such as supercap technology and also, increasingly, lithium-ion batteries are therefore gaining ground. However, when it comes to efficiency and performance, there is still considerable room for improvement, especially in the area of energy supply. New inductive charging solutions promise a clear rise in productivity.

What are the battery types and battery chargers?

In large warehouses, shuttles convey valuable freight through long lines of shelving. The shuttles need sufficient power to get from the material pick-up point to the unloading point. Older systems in particular still use copper conductor lines to supply power. In view of rising raw material prices and a worldwide shortage of resources, warehouses are now clearly starting to avoid using copper rails.

Modern approaches are therefore increasingly choosing to charge in elevators and in charging stations. Nowadays, charging contacts are used for this. Because the processes in shuttle systems are highly dynamic, there is a time window of roughly ten to fifteen seconds available for charging in the elevator. During this time, however, precise positioning in the elevator takes place first, before the shuttles are supplied with power via the charging contacts. This means that up to 50% of the possible charging time is taken up by alignment. Particularly in dynamic applications like these, new power charging concepts such as inductive charging technology can lead to a significant increase in transmissible energy: Inductive charging allows immediate charging from the beginning of the lift travel and thus offers the prospect of high productivity increases.

Supply of power to kilometers of copper conductor lines

In traditional shuttle storage solutions, vehicles charge conductively by running across copper rails in the aisles to which electrical current has been supplied. But there are several reasons why copper conductor lines are not the best charging option. Permanent electrification of a warehouse represents a very high cost factor. Investing in vast quantities of cables, incorporating three or four copper rails each, is a massive waste of resources. In an average logistics warehouse using shuttles, over ten kilometers of cable with copper profiles are needed to supply power to the individual aisles.

In addition, the conductor lines and contacts quickly wear away over the time they are used because of the constant friction on the shuttles during travel. If a running rail is not perfectly aligned, the shuttle’s current collectors become worn at the edge of the conductor line. This means that the system wears out very quickly. Consequently, to ensure that moving into the aisles works optimally and wear and tear are minimized, installation must be as precise as possible. With systems over a certain size, an employee therefore checks the shuttles constantly and changes individual contacts if necessary.

By ceasing to use copper rails and changing over to other energy sources, companies with large warehouses will save 30 tonnes of copper, on average. This not only gives an efficient cost-benefit ratio for the logistics operation, it also benefits the environment.

Power supply with charging contacts and supercaps

At the moment, many logistics companies are choosing to fit their shuttle systems with supercaps. These capacitors have a much higher power density than accumulators. With their almost endless working life, they can run through millions of charging cycles. Today, supercaps are charged using charging contacts in elevators as standard.

Once a shuttle has entered the lift, the stationary charging devices only start charging after precise positioning. The lift process takes ten to fifteen seconds. By the time the monitoring of the contacting is completed and the contact has been made cleanly, up to 50% of the possible charging time is lost in the transport process. Depending on the size of the shuttle, lowering units may be needed in order to access the contacts on the lift at all. The constant friction of the current collectors during travel causes damage at points on the contacts over time, leading to permanent wear. Lift loading and unloading using charging contacts can therefore involve a high level of maintenance.

Inductive charging increases the productivity of shuttle applications

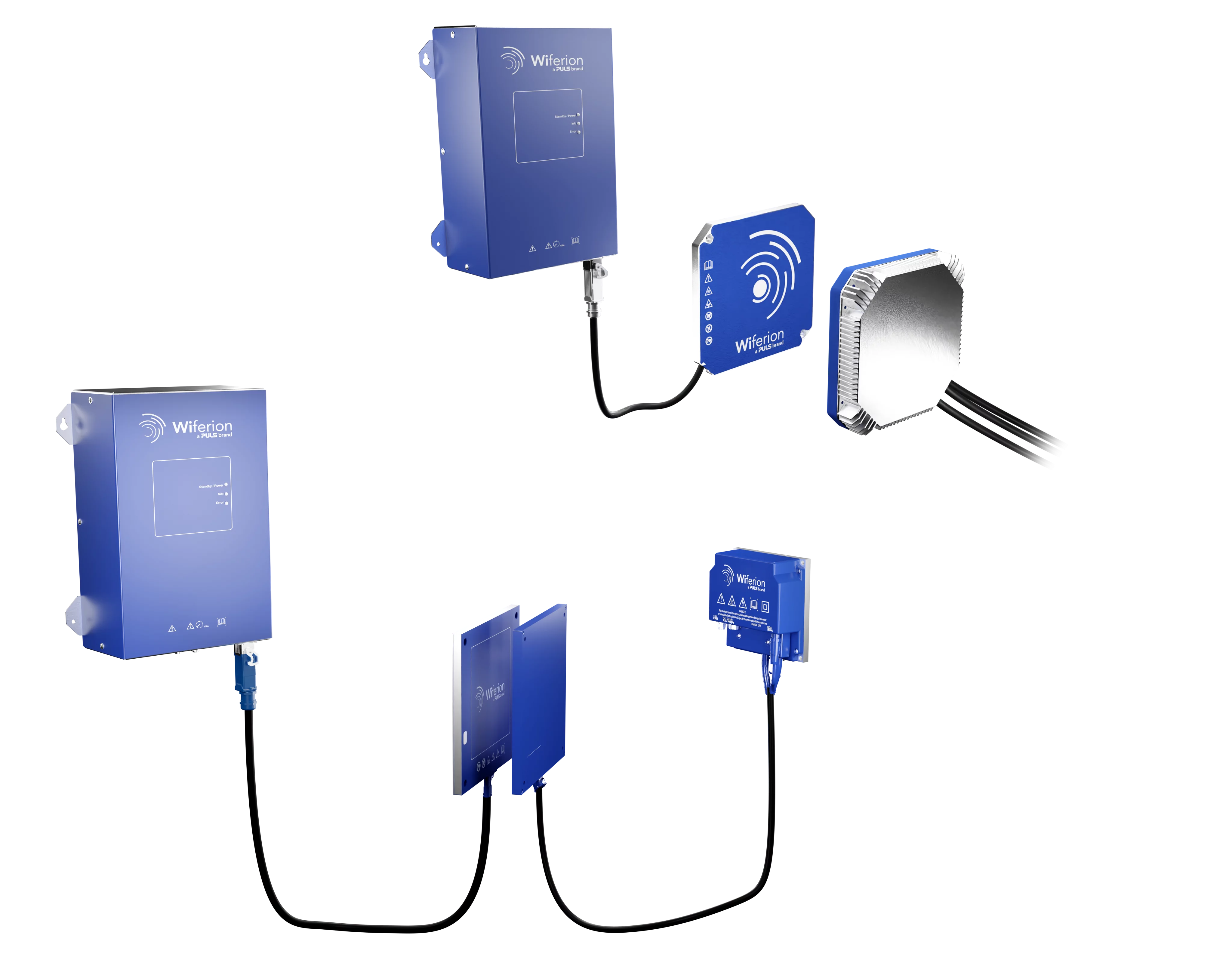

Until now, inductive chargers were too large for use in shuttle systems. Thanks to Wiferion’s patented charging system, they can now be used for shuttles for the first time, making these far more efficient. The charging technology is extremely compact, easy to install and compatible with supercaps. The charging electronics installed in the shuttle has a thin mobile coil and takes up very little space. Wiferion’s smart charging system thus allows shuttles to be supplied with power more cheaply and efficiently than the current standard charging technology using charging contacts or conductor lines.

With inductive charging systems, there is no need for the positioning process at all. Because of the high level of positioning tolerance, the shuttle does not have to be positioned precisely in the middle when it enters the lift to initiate charging. Because power transmission is contact-free through the air, there is also no need for the lowering device. The supply of power at full efficiency starts in less than a second, as soon as the shuttle reaches the charging point. The usable charging time is thus up to 50% longer, which also increases the travel time of the shuttles. With hundreds of elevator runs per day, this gives massive increases in productivity. In addition, the encapsulated systems are 100% maintenance-free, guaranteeing reliable operation at all times and a good solutions for automated storage and retrieval in high throughput logistic warehouses.

Technology also suitable for automatic warehousing and order picking systems

Wiferion’s inductive charging technology increases the efficiency, performance and service time of shuttle systems. However, investing in a modern energy solution that saves on resources is not just beneficial for large high-bay warehouses, product warehouses, storage system and shuttle applications. Inductive charging technology is also ideal for the increasingly popular robot-aided small parts stores in the e-commerce sector. Simple charging of the robots with carrier parts that are becoming ever smaller requires a flexible, compact charging solution that supports short charging times.

Why is inductive charging the more efficient alternative for shuttle systems?

Inductive charging systems are an efficient alternative to charging contacts and conductor lines used as standard in shuttle systems. With this, warehouses benefit from a maintenance-free, robust, reliable charging technology. Unproductive elevator times can be halved. Inductive charging technology is also characterized by more cost-effective, increased power supply. This brings a clear increase in the productivity of shuttle systems and robot-aided small parts stores.