多合一感应式电池充电系统和锂电池

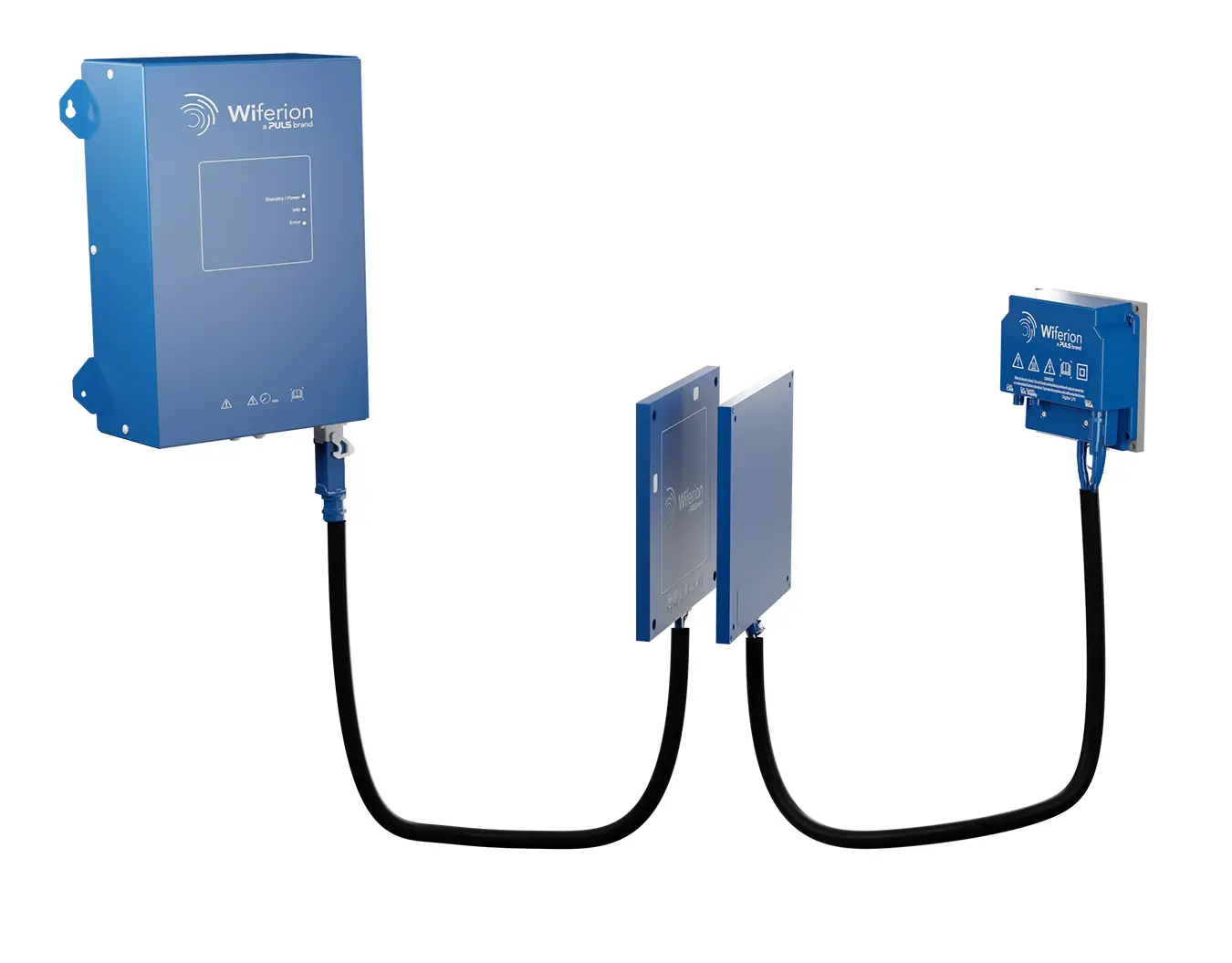

Wiferion 产品 – 感应式工业充电系统

产品概述

无线产品类别

01 壁挂式充电盒 / 02 充电板 / 03 接收板 / 04 移动充电装置 / 05 能量存储 – 电池

面向工业应用场景的感应式充电系统产品(充电功率 1 kW 至 9kW)- etaLINK 系统

达到 IP65 防护等级的无接触、无磨损即时充电

采用专利技术的 etaLINK 3000 和 CW 1000 系统专为工业车辆的感应式充电研发,适用于移动机器人和 AGV 的无线充电。 我们设计的电池充电系统考虑到了新一代自动驾驶车辆和机器人系统的智能性和自主性。 它们可以方便地独立安装,并为车辆提供所有相关数据。 用户可将多套系统串联,即 2 套功率为 3 kW 的 etaLINK 3000 系统串联后的充电功率可达 6 kW,3 套 etaLink 3000 系统的充电功率可达 9 kW。

感应式无线充电系统无需充电触点

由于消除了机械充电触点,用户可以方便地将电池充电整合到现有流程中,从而实现电池的中间充电。 这样既节省了时间,又消除了触点开路带来的潜在危险。 etaLINK 机会充电系统具有免维护的特点,可连续多年不间断运行。

无线电池充电 – etaLINK – 无线电池充电站

无接触感应式无线电池充电系统,适用于工业环境中的自动运输车(AGV)、机器人和工业卡车。 车辆进入充电站之后,充电过程将立即启动。 无接触设计意味着 Wiferion 无线充电产品可根据您的流程需求放置在任何地方。 在 1 秒钟之内,充电过程就能顺利启动。 优化后的锂电池感应式无线充电系统可通过集成的 CAN 总线接口与车辆部件通信,因而成为完美的边用边充系统。

锂电池技术

改变电动车辆供电的游戏规则

过去十年中,锂电池已从一项小众技术发展成为最先进的电动汽车能量存储技术。 尤其是在物料搬运领域,与传统铅酸电池相比,现代 AGV 电池充电系统的优势显而易见,而且投资回报率更高。

etaSTORE 锂电池

根据应用场景的需求,Wiferion 还可为感应式无线充电提供不同类型的电池。

每一种类型均可提供:

24 V 和 48 V 系统

充电电流为 20 Ah – 250 Ah(按 0.5 kWh-12 kWh 装机储能计算)

基于 CAN 的用户界面,可访问充电状态、健康状态、电压、电流等数据。

全能型电池(磷酸铁锂)

全天候 AGV 应用场景的最佳解决方案

优势速览:

高循环寿命:>8500 次完整循环

100% 放电深度

1 C / 1 C 充电/放电电流

80% 剩余报废容量

大电流:1-2 C 充放电速率(1 C 等于系统容量(单位:[Ah])除以 1 [h])

磷酸铁锂电池具有放热电位低的特点,电池芯还配备断流装置(CID),因此内在安全性较高

多个安全中断装置确保系统高度安全

高标准:UN 62133(美国市场)和 EN 62133(欧洲市场)

采用索尼/村田电池芯,确保生产质量最高、生产成本最低

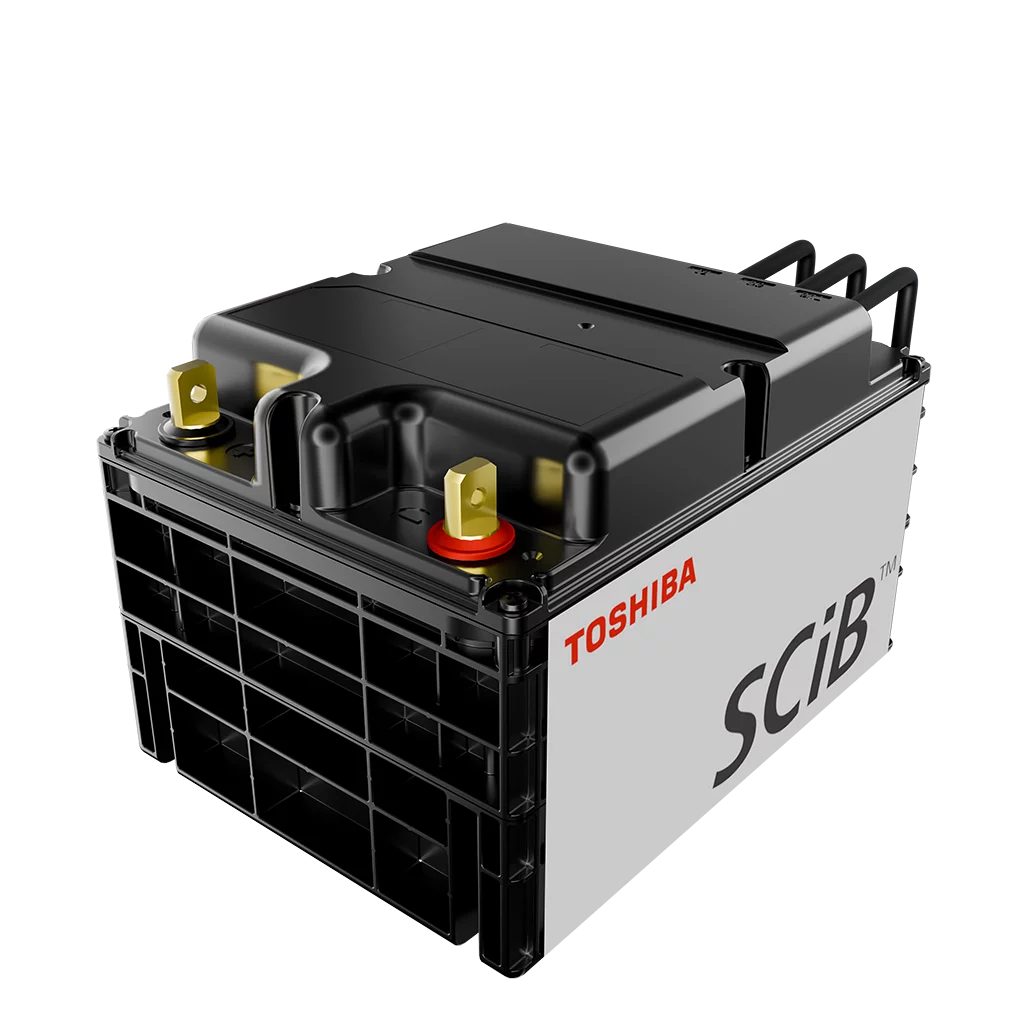

动力电池(钛酸锂)

非常适合充电电流超过 200A、每天充电超过 10 次的重型应用场景

优势速览:

高循环寿命:>100% 放电深度下可实现 17,000 次完整循环和 80% 剩余报废容量

100% 放电深度

6 C / 6 C 充电/放电电流

80% 剩余报废容量

最高功率能量比:约 4 C 充电和放电,每 1 kWh 装机能量可获得 4 kW 放电功率(= 160 A @ 45 Ah 装机容量)

最高温度范围:全功率充放电温度范围约为 -20°C-50°C

最高国际标准:IEC 62619

保证以最低生产价差实现最高日本生产质量

etaTRAY – 叉车改装

无线感应式电池托架

集成感应式充电系统和锂离子电池的标准电池托架。 工作过程中可随时直接对叉车和 AGV 的电池进行无线充电。 该系统没有充电插头和触点,可为自动化创造理想的条件。 感应式充电系统可帮助您节省时间、提高安全性和可靠性。

叉车无线供电

方便、快捷地更换老旧电池系统

用紧凑型标准化托架升级电池系统,集成 etaLINK 3000 接收装置

模块化容量规格

电池电压:24V-48V

充电电流:60A-180A,可扩展