The increasing shortage of skilled workers is presenting many medium-sized production operations, especially contract manufacturers, with major challenges. With shift working in particular, it is becoming increasingly difficult to maintain 24/7 production. GER4TECH is the first supplier to enable small and medium-sized enterprises (SMEs) now to automate their handling and logistics processes on a mobile basis with a collaborative robot solution specially tailored to the needs of contract manufacturing. Wiferion’s inductive battery charging system plays a vital role in this.

Automatic loading of machine tools

To survive in the hard-fought contract manufacturing market, tool machines such as turning, milling, wire eroding or sanding and any types of machining machines must run around the clock. But this requires skilled workers – and they are hard to find at the moment. Fewer and fewer companies are managing to maintain a three-shift operation all the time. Another problem: CNC machines are often loaded manually. Parts are increasingly being left for too long after processing before they arrive at the next machine for further processing. While large companies respond to the situation with elaborate automation concepts, SMEs in particular urgently need more flexible concepts.

First autonomous mobile robot (AMR) with a 6-axis robot

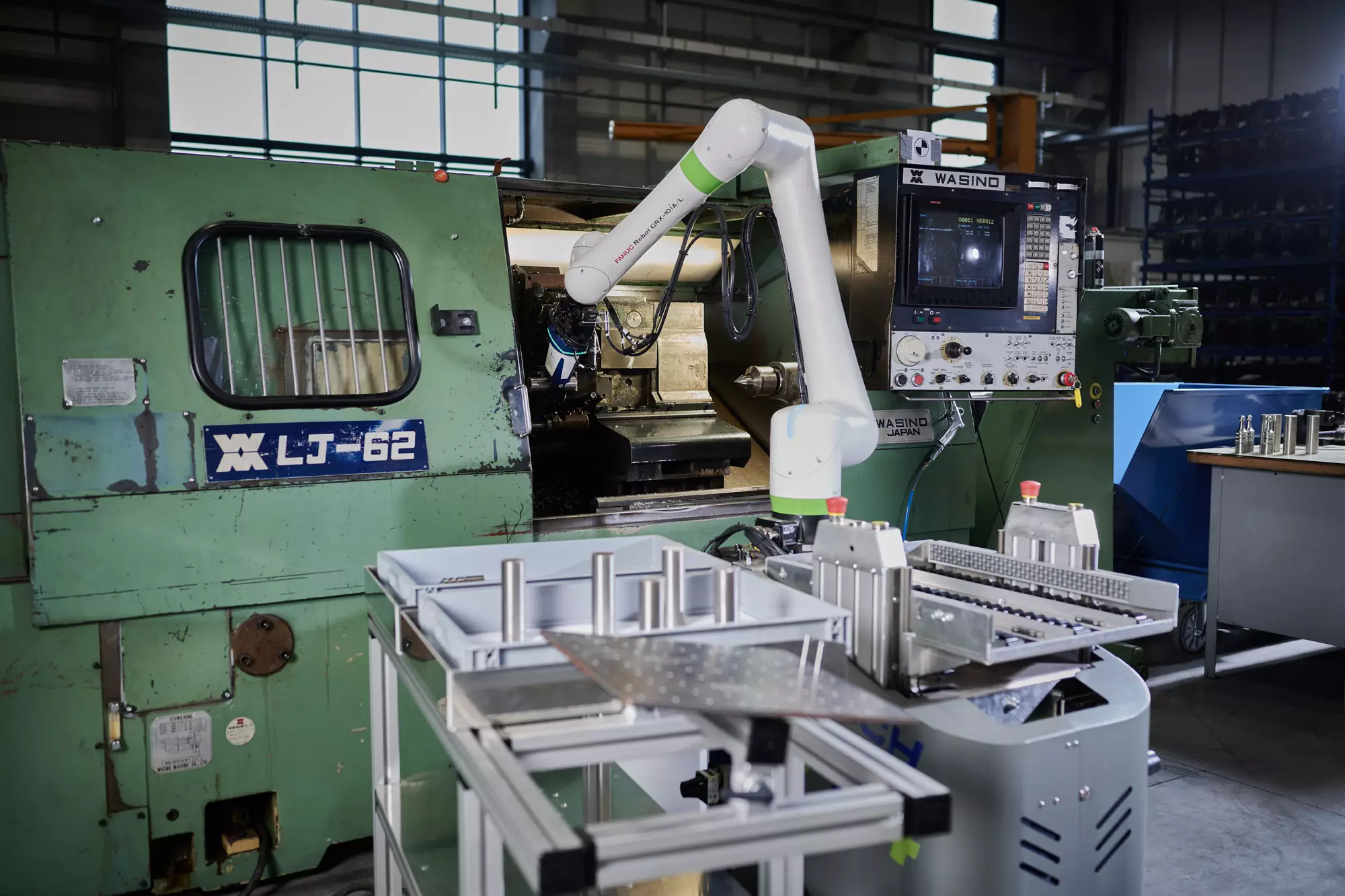

Admittedly, here too robots are increasingly being used with the processing machines that load and unload the components, but these need to be housed and they work on a stationary basis. And the mobile shuttles available on the market are hardly, as yet, suitable for use in additiv and subtractive manufacturing, as they are basically designed for the logistics sector. GER4TECH, working with Fanuc and Incubed IT, has undertaken to close this gap in the market: The Mobile Cobot G4T4 is the first autonomous mobile robot (AMR) with a 6-axis robot that is specially designed for manufacture.

A fusion of cobot and AMR

The G4T4 is a fusion between a collaborative and a mobile robot. The mobile cobot can move autonomously between various work areas, change easily from one job to the next and also transport and remove material at the same time. “Our mobile cobots independently find their way to the next task, even in environments that are totally chaotic”, says Hubert Gerstmayr, CEO of GER4TECH. The G4T4 cobots are thus opening up whole new possibilities for contract manufacturers when it comes to the automation of their handling and logistics processes.

The CRX is a cooperative lightweight robot that is used without additional protective devices

Essentially, the G4T4 is an AMR on which a Fanuc CRX-10iA/L cobot is mounted. The CRX is a cooperative lightweight robot that is used without additional protective devices. “With its low weight of just 40 kg, it is ideal for use on mobile platforms”, Gerstmayr explains. This means that the robot is able take over both handling applications for tool machines and also the transport of raw materials and finished parts, tools, pick and place applications and tasks in warehouse commissioning and even to combine them.

Dynamically deployable CoBot

The G4T4, for example, can pick up Euroboxes with HSK mountings for a rotating spindle of a wire eroding machine from a central storage location, as seen in the trade fair application at Intertool in Wels. After requesting the part, the robot drives to a tool machine and carries out an offset calibration. After this, the cobot arm takes an HSK mounting with a finished workpiece out of the machine and places it in a free position in the Eurobox. The cobot then loads the machine with an HSK mounting with a blank from the Eurobox and then transports the finished workpieces to a central storage location or a downstream tool machine.

Precise positioning to the workpiece

One of the major challenges when using robots on mobile platforms is not only precise positioning in relation to the machine or work station, like traditional industrial robots, but also precise positioning in relation to the part or tool mounting of the processing machines. A camera and software are used to determine and calculate the exact position of the robot in relation to the machine. The G4T4 thus combines maximum flexibility with excellent positioning precision and repeat accuracy.

Wireless charging is the key technology

For GER4TECH as a system integrator of customized automation solutions, reliable 24/7 operation is the top priority. The power supply to the robot’s lithium ion battery is therefore crucially important. Wiferion’s installed inductive battery charging system etaLINK contains no parts subject to wear, thus guaranteeing maintenance-free continuous operation of the mobile cobot. “Wiferion is the only supplier to offer a contactless charging system that has long proved successful in industrial environments”, Gerstmayr explains. Because GER4TECH also obtains its lithium ion batteries from Wiferion, the automation specialist is able to obtain a complete, perfectly matched energy system from one source. “With Wiferion, we have a vast range of options for designing a system that is flexible and offers advantages to the customer. It was therefore clear to us from the beginning that we would only be integrating this technology.”

“Wiferion is the only supplier to offer a contactless charging system that has long proved successful in industrial environments”, Gerstmayr explains. “With Wiferion, we have a vast range of options for designing a system that is flexible and offers advantages to the customer. It was therefore clear to us from the beginning that we would only be integrating this technology.”

“With Wiferion’s etaLINK system, a number of mobile robots can share a charging station. It is also possible to read out all the relevant data from the batteries and the mobile charging electronics via a CAN interface.”

the entire automation process is transparent

The contactless design means that the cobot charging system can be placed anywhere where longer working times for the cobot are likely. Energy is supplied in-process, i.e. directly at the tool machine, via “in-process charging”. Thanks to the increased positioning tolerance, simple positioning of the mobile robot in relation to the charging point is possible. In addition, the entire automation process is transparent and much easier to plan. It is thus possible to define precisely when the robot should be charged and how long charging will take.

As a result, processing steps can be planned exactly and are not interrupted by charging breaks and no extra time charges. For Hubert Gerstmayr, the system has a further advantage: “With Wiferion’s etaLINK system, a number of mobile robots can share a charging station. It is also possible to read out all the relevant data from the batteries and the mobile charging electronics via a CAN interface.” In this way, GER4TECH can offer its customers an even better service. In addition, safety at work is also improved, as etaLINK is an enclosed system without open charging contacts.

Summary

With the G4T4, GER4TECH is offering the first mobile cobot for manufacturing purposes. The mobile handling solution automates the transport of materials such as raw materials and finished parts to and from tool machines. The charging system requires no plug-in or sliding contacts, which allows in-process charging of batteries. This saves time and increases productivity. Even in continuous use, the G4T4 can be operated for many years without maintenance of the power supply.