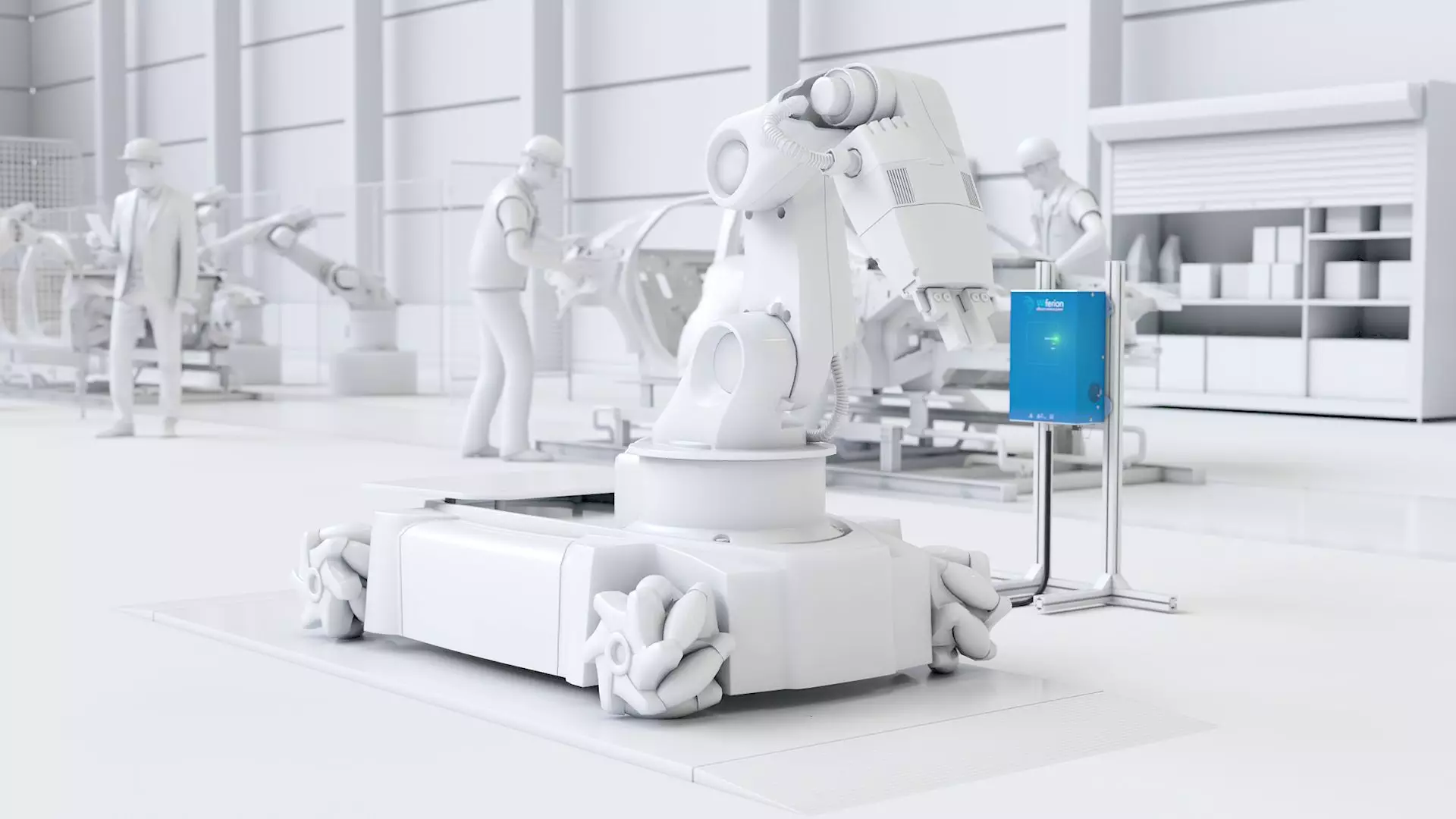

适用于 AMR(自主移动机器人)的无线供电,可进一步提升生产力

适用于 AMR(自主移动机器人)的无线供电,赋予更强大的前景。 从“人到货”和“货到人”到运输、操作和分拣任务——未来工厂需要移动性和灵活性。 自主移动机器人(AMR)和 AGV(自动导引车)适用于生产和物流中的多种自动化任务。 通过自主移动、协同作业,实现业内最佳灵活性——系统以充足的能量,实现完整的自主化。

全自动,始终获得所需能量

与固定式容器或托盘输送技术相比,AMR 的巨大优势在于其灵活性。

借助人工智能或机器学习,系统可以自主决定何时执行何种任务。

通过 AI,系统将根据仓储布局的变化,自动调整运输路线。

此外,通常会在最短时间内完成操作。

通过我们的非接触式充电系统,移动机器人将全自动地、实时地获取完成任务所需的能量。

车辆无需因充电而中断工作流程。

感应式充电是实现最佳自动化生产率和系统 24/7 不间断运行的关键。

AMR 集成感应充电的精选客户与合作伙伴

物流与生产行业的 AMR(自主移动机器人)无线供电

结合我们的 etaLINK 系列无线供电系统,AMR 将无需任何插头或滑动式连接。

我们的能源解决方案由一个壁挂式充电盒和一个充电板组成,可安装在物流和生产环境中最频繁使用的地点。

功能强大的移动电子设备,规模紧凑。

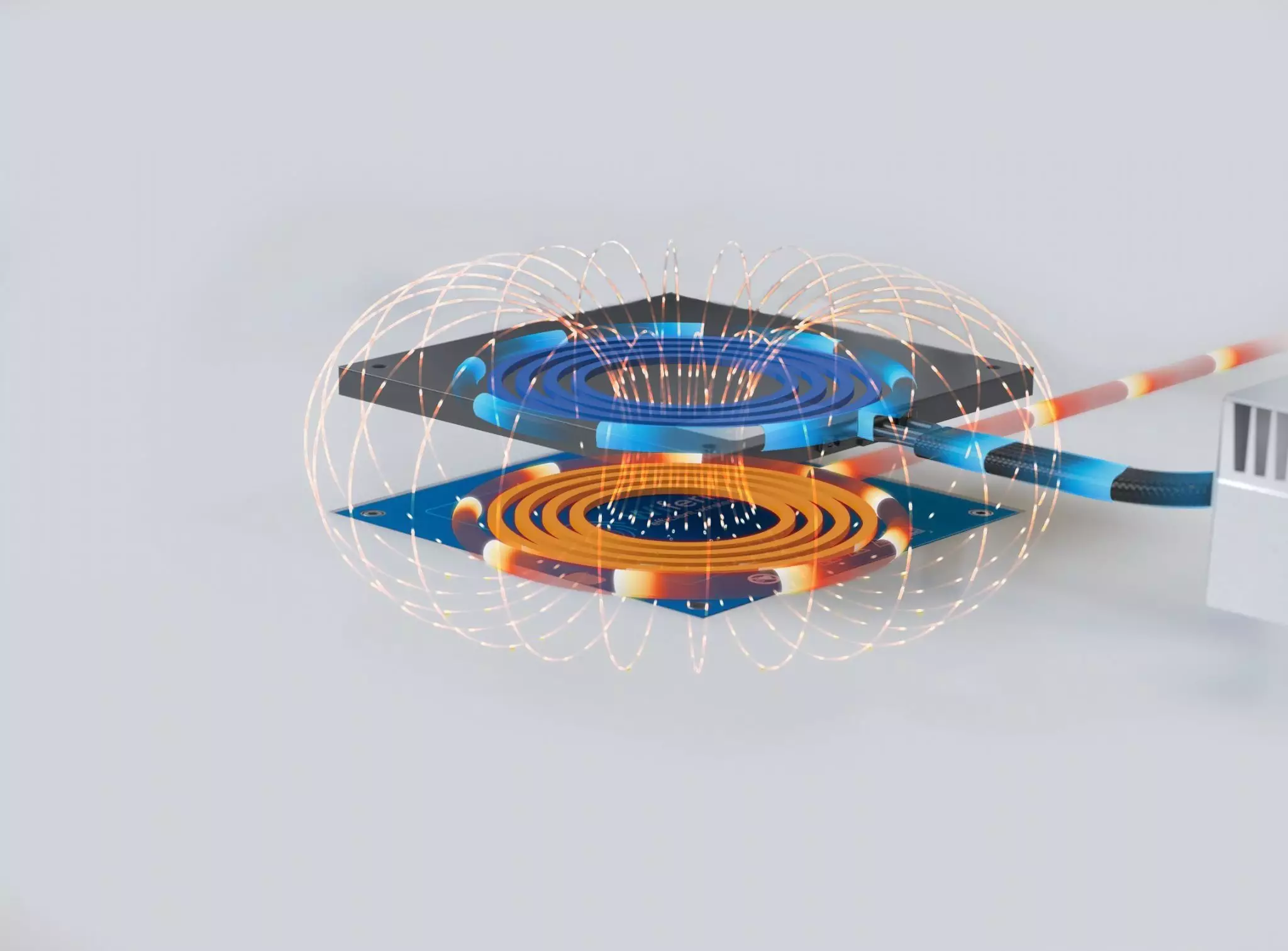

获专利的接收线圈、移动充电装置和储能装置可集成至移动机器人,节约空间,实现感应式充电。

在物流环境中,当 AMR 靠近充电点时,一秒内将全自动开启能量供应。

etaLINK 的效率高达 93%,因此移动机器人可在最短的停留时间内高效地接收能量。

此外,充电站还支持全向充电。

无线供电如何提升 AMR 的效率?

Wiferion 的新一代无线供电技术实现了“作业中充电”。

在生产和物流作业中,自主移动机器人会在运行中获得短时补能,从而保持系统能量水平的恒定。

车辆可全天候连续执行运输任务,而无需为充电中断物流作业。

一个充电站可支持 24 至 48 伏的不同电池,并且可自由编程充电特性。

Wiferion 的产品通过集成的 CAN 接口与车辆部件通信。

从而确保了无热量产生的最佳充电过程、高度的流程可靠性、必要数据的完整传输。

面向自主车辆的免维护无线电池充电技术

AMR 在处理小件货物和产品方面效率极高。

紧凑型尺寸发挥了关键作用。

更小的电池,塑造了更加纤巧的移动机器人。

由于我们的无线供电产品能够让机器人能量水平始终保持高位,因此我们减少了电池的容量范围。

维持运行所需的电池容量最多可减少 30%。

感应式充电实现机器人的免维护能源

由于我们开发的充电系统没有机械滑动接触,因此,我们的充电系统无需维护。 这给机器人和 AGV 提供了极大优势,因为,氧化的插头或断裂的电缆常常会导致系统停机。 因此,感应式充电可让您的自动化更可靠。

迅速开启的感应式充电

灵活性和快速落地是移动机器人的特点,因此传统充电技术所需的施工延误往往适得其反。

Wiferion 的 etaLINK 系统可实现灵活的安装。

将充电板安装到墙面、地板、行车道、停车区或装卸站,仅需几天。

可根据布局变化调整安装位置,操作步骤便捷有效。